3 Key Metrics to Optimize AM Profitability

The value-added benefits of additive manufacturing (AM) versus traditional methods are already well known. Reduced costs and shortened lead times, coupled with greater design freedom and the ability to print more complex parts, are all factors driving the take-up of AM in industries ranging from automotive to medical, aerospace to fashion, maritime to food, and more.

Yet, how can you quantify the benefits 3D printing delivers for your business and ensure you are optimizing the Return On Investment (ROI) of your AM processes? According to a report by 3D printing service Scultpeo, the budget remains the biggest barrier to adopting and expanding AM operations.

Screenshot from Sculpteo’s The State of 3D Printing 2020 report. Image via 3YOURMIND.

“We know data is the new currency, and by making real-time evaluations visible, AM facilities have the framework they need to make the best decisions for increasing profits,” said Stephan Kühr, CEO and founder of 3YOURMIND.

3YOURMIND has organized the upcoming edition of 3D Talk Show to discuss the following KPIs businesses should consider when looking to increase the profitability of their AM operations. According to the company, customer management, workstation utilization, material management, and cost predictions are all metrics through which Industrial companies and service bureaus can achieve this, and will be discussed in depth during the webinar.

Customer Management

Fundamental to running an efficient, profitable AM business is customer management. Gaining an informed understanding of their customers’ behaviors will better enable firms to adapt to their specific requirements. Access to accurate data, therefore, is key to establishing realistic growth goals and measuring the performance and value of ongoing projects.

To this end, AM profitability can be enhanced through customer management by tracking order cycle times, individual orders per customer, the type of customer they are, and the average value of their orders. Analyzing this data can enable AM firms to better understand the behaviors of their customers, and how best to serve them. In turn, this provides indicators as to where profitability can be improved on a customer-by-customer basis.

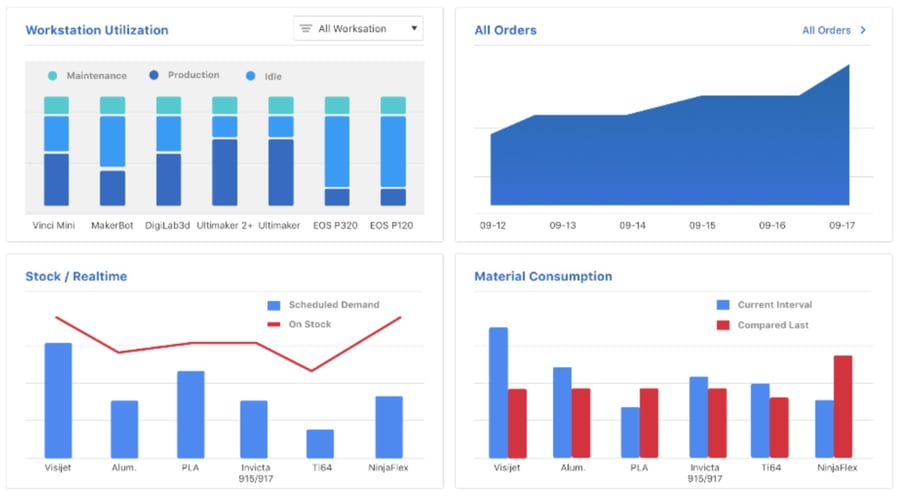

The dashboard of 3YOURMIND’s Agile Manufacturing Software Suite. Image via 3YOURMIND.

Workstation Utilization and Material Management

Another important consideration when maximizing profitability is workstation utilization, in short, how efficiently managed is your workstation? The key to this is making sure 3D printers are operating at 100% capacity to reduce downtime significantly. Continually tracking the maintenance of machines will also allow any problems that arise to be solved quickly, further reducing downtime and unforeseen pausing of jobs. Tracking jobs is also necessary to be able to successfully print various parts for different customers at the same time, boosting operational efficiency and, therefore, profitability.

In a similar vein, the ability to efficiently manage the materials used within orders could significantly boost profitability. Accurate predictions of how much material will be needed for each job helps to reduce waste and unnecessary overuse of expensive feedstock. Meanwhile, re-using leftover materials such as powders can also help to reduce waste. Tracking the profitability of the materials used can thus provide significant cost savings while providing indicators as to where the management of materials can be optimized.

3YOURMIND’s workstation utilization dashboard. Image via 3YOURMIND.

3YOURMIND’s workstation utilization dashboard. Image via 3YOURMIND.

Predicting Costs

Finally, cost prediction can also be fundamental to operating a profitable AM business. Being able to track the individual components of each job in real-time, and their subsequent costs will provide firms with the real cost of a job as opposed to an expected one. Tracking the order as it is completed and taking into account the costs of any unforeseen hindrances will therefore enable firms to give an accurate fee of what the job has actually cost to complete.

Operational costs can also be lowered by reducing the number of steps in the production process. By implementing the 3YOURMIND platform, a leading automotive OEM customer was able to reduce the number of steps in the production process from 11 to nine, speeding up the process by 38 minutes. The OEM’s project coordination process was also reduced from nine steps to five, saving eight minutes. In total, these efficiency improvements delivered an estimated $400,000 savings per site each year for the customer.

To learn more about how to justify costs for AM - watch our episode of the 3D Talk Show with Elena Laso Plaza (HP), Stefanie Brickwede (Mobility Goes Additive), Naomi Murray (STRYKER) & Kristin Mulherin (AM-Cubed)