3YOURMIND Supports the SIMMT With 60 3D Printers in France

Paris, France, July 1st, 2021 – The area of use for additive manufacturing in the military sector is vast, both from a logistical and industrial point of view. It enables a quick, decentralized, and flexible production of parts that would have been too expensive or too time-consuming to be manufactured using traditional methods. The potential to increase performance, reduce manufacturing costs, and deploy more advanced engineering solutions is considerable. The success of 3D technologies points to a possible relocation of production, the relevance of which is demonstrated by the current health situation.

The SIMMT is the sector of the French Army in charge of the maintenance of land equipment in operational condition. Being part of the infantry, in addition to working for the benefits of other parts of the army, the SIMMT having the functional authority over the entire maintenance of land equipment in operation is no small order.

Let's take a look at this specific case, and how SIMMT's decentralized production with its fleet of 60 FDM 3D printers is managed.

The management of Additive Manufacturing by the SIMMT

The SIMMT sees many advantages in additive manufacturing, particularly in vehicle maintenance, spare parts repair, and tooling manufacturing. It has taken a close interest in additive manufacturing technologies for a few years now:

- 2019 : Acquisition of one PRODWAYS plastic printer

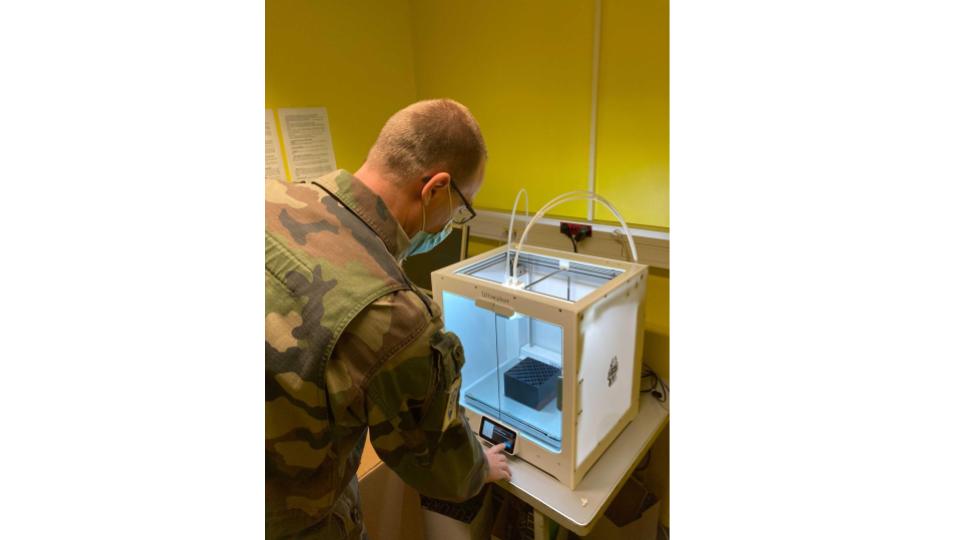

- 2020 : Acquisition of 60 ULTIMAKERS FDM 3D printers to meet equipment shortages during the COVID-19 pandemic, making it one of the largest 3D print farms in Europe.

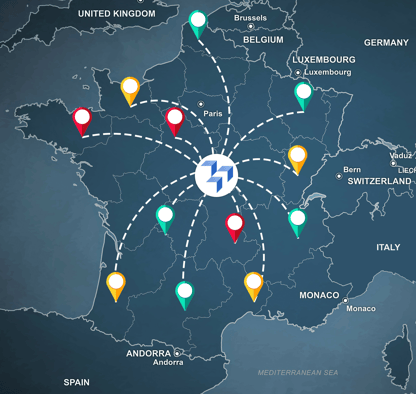

- Summer 2020 : Distribution of 3D printers to the various maintenance regiments in France.

Which challenges is the SIMMT facing in deploying additive manufacturing?

Initiating a print – The SIMMT

Initiating a print – The SIMMTFaced with the fast development of its 3D activity, the SIMMT had to find a solution that is easy to implement in the different regiments, to address the following challenges :

1. In the regiments :

Challenge 1 : Ensuring that printed parts are checked beforehand and that operators have all the data they need to print a standard part.

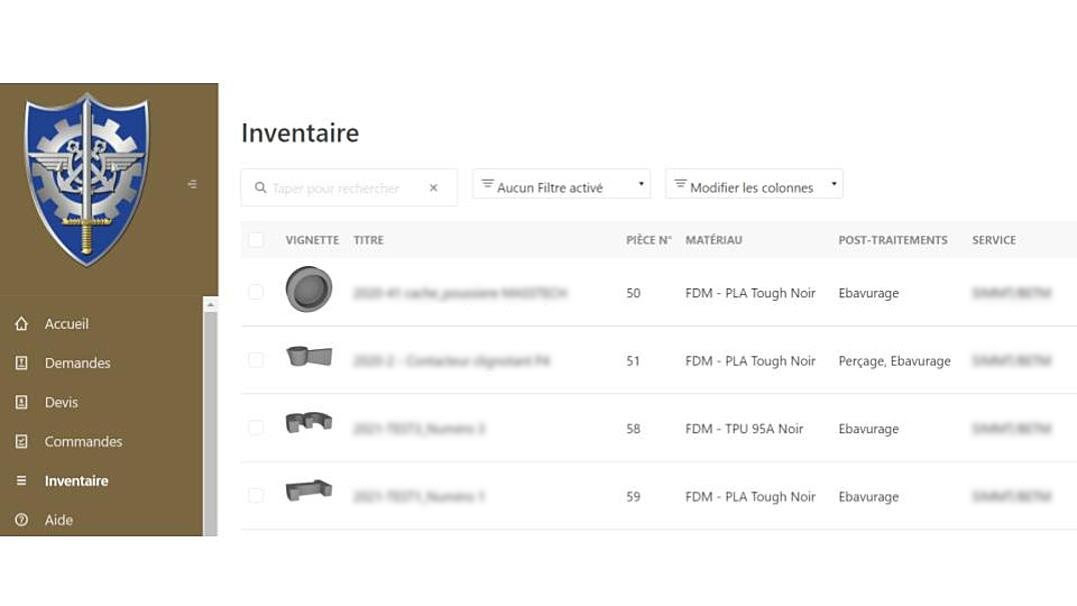

Solution : Centralized parts catalog accessible to the different maintenance regiments

3YOURMIND’s Agile ERP module integrates a digital catalog which allows the storage of parts eligible for AM. This catalog, accessible to all regiments through the platform, offers centralized essential data for the production of a part: 3D file, printing file, manufacturing range and other useful information. Thus, it is easy and intuitive to initiate a production order based on the information given in the catalog.

Each operator has their own personal login data to the platform, which allows for complete traceability and transparency of the flows. Digital parts catalog on the SIMMT ERP platform by 3YOURMIND

Digital parts catalog on the SIMMT ERP platform by 3YOURMIND

Challenge 2 : Managing the parts production according to the need and order of priority as well as ensuring that the stock of materials is sufficient.

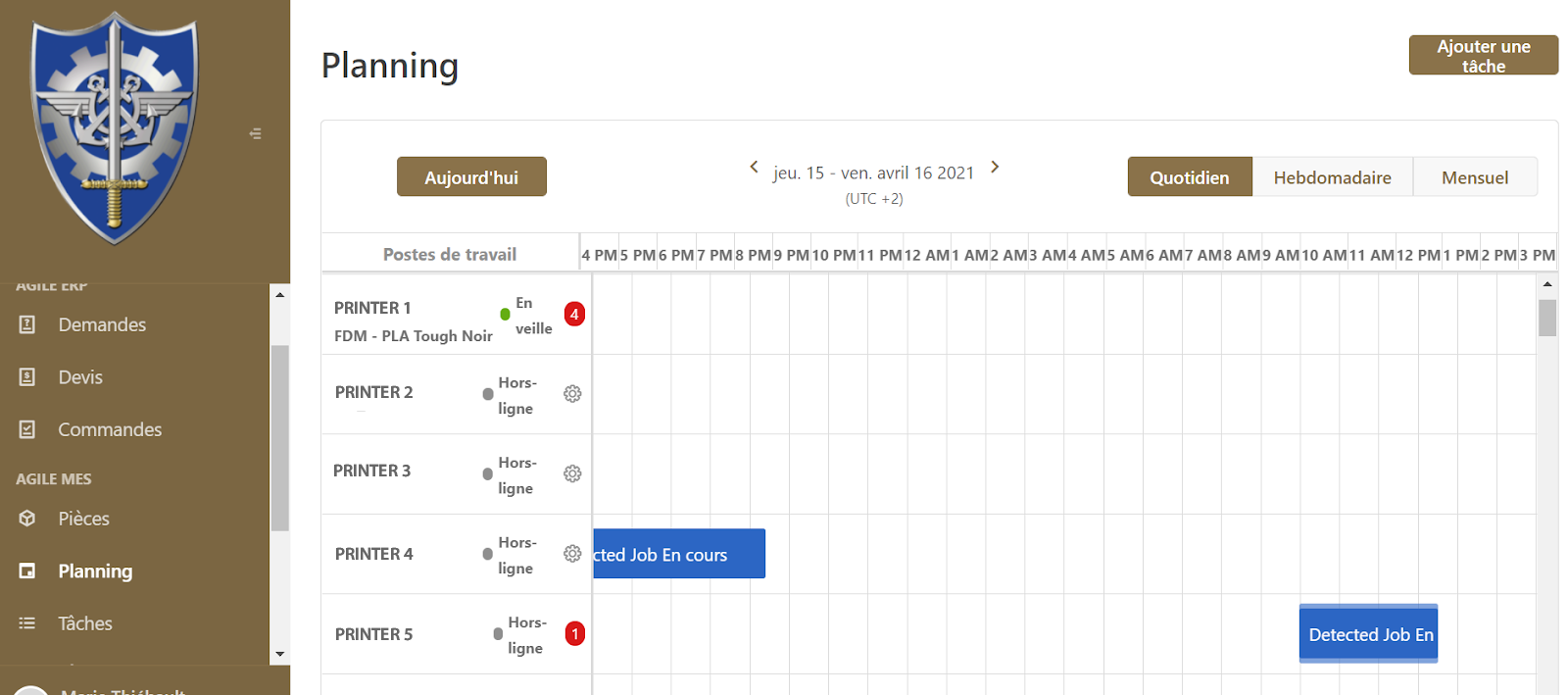

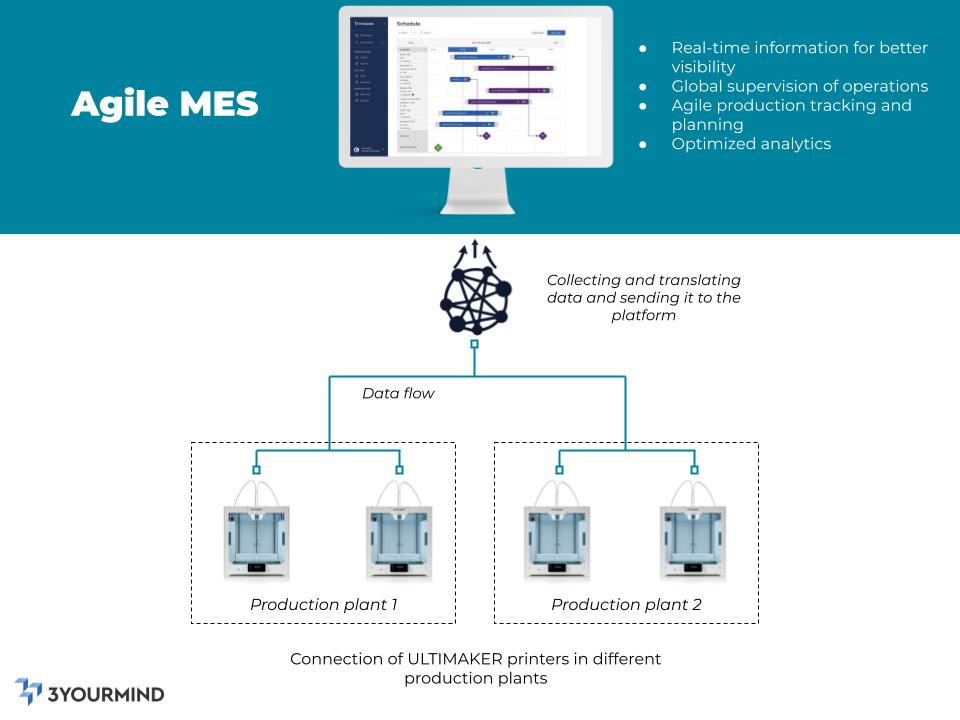

Solution : Production management with Agile MES (production workflow and machine utilization optimization)

Thanks to the connection between the parts catalog and 3YOURMIND’s production management module MES, the operator has access to all the parts before being printed, during printing, or when ready to be shipped. The digital planning tool allows managing all the production steps, and to have them visualized on the platform.

Thanks to the connectivity between the ULTIMAKER printers and 3YOURMIND’s Agile MES module, the information from the printers is collected, translated, and sent to the control platform. The production data is visible in real time, with the estimated time of completion of printing and alerts or incidents on the printer also shown on the platform. The combination of the different functions of the AGILE MES ensures an optimized and streamlined production flow.

2. Supervision of Additive Manufacturing by the SIMMT at a Global Scale

Challenges within the SIMMT

- Anticipating budgets

- Having an overview of the use of the printing capacity

Solution to ensure the management of the 3D activity

- Performance indicators for profitability

We know that data is the new currency, and with real-time production monitoring, AM production centers can improve decision making and increase benefits,” says Stephan Kuhr, CEO and founder of 3YOURMIND.

In order to give the controlling unit of the 3D printing activity all the necessary means to measure productivity, 3YOURMIND’s software suite provides performance indicators for the entire AM operation, regiment by regiment. This includes a complete and ongoing analysis of the processes within the value chain. The main key performance indicators (KPI) for the SIMMT processes are the number of parts ordered and delivered, the machine utilization rate, the material consumption...This allows the controlling unit to better understand the behavior of its 3D units, how best to support them, but also to create “harmony” within the process overall.With this centralized platform and standardized process, the 3D printing activity manager has all the keys in hand to be reactive and proactive, to anticipate the material needs, and to do so remotely from any location, at any time. This is essential for a decentralized production system.

Overview of production sites

Overview of production sitesConclusion

The challenges faced by the SIMMT within its additive manufacturing processes are not isolated. Many entities within the military sector, but also in other industries, are looking to optimize their decentralized additive manufacturing. Standardization and simplification of additive manufacturing workflows are critical to the successful coordination of production and ensuring return on investment. Today, thanks to having worked with numerous customers, such as the SIMMT, 3YOURMIND has developed a complete modular solution for successful decentralized 3D production. Vistory was in charge of the IT deployment and the implementation of the 3YOURMIND solution on the architecture.

About 3YOURMIND

3YOURMIND's unique AM workflow software enables industry leaders to build on-demand distributed production models. 3YOURMIND offers end-to-end software to automate, track and document each step of the value chain. Our Agile Manufacturing Software Suite provides modules that standardize every aspect of the supply chain from the creation of digital qualified parts inventories to the management of orders and the optimization of the production process. The Agile PLM module analyzes part metadata to build a digital inventory of AM-ready parts. The Agile ERP module automates pricing, order taking and customer management. It also centralizes data and allows end-to-end traceability of information. The Agile MES module optimizes scheduling, increases transparency and ensures quality monitoring along the AM production chain. With end-to-end transparency, traceability and flexibility, the software lays the foundation for the future of automated and reactive manufacturing. 3YOURMIND is a global organization with headquarters in Berlin, Germany and satellite offices throughout Europe and the United States. Learn more at www.3yourmind.com.

About the SIMMT

The SIMMT is the sector of the French Army in charge of the maintenance of land equipment in operational condition. Being part of the infantry and, in addition, working for the benefits of other parts of the army, the SIMMT has functional authority over the entire maintenance of land equipment in operational condition. Learn more at https://www.defense.gouv.fr/terre/l-armee-de-terre/les-grands-commandeurs/dc-simmt

Going Further...

To learn more about the Defense Industry and Additive Manufacturing, read our article "3 key missions for the Defense industry to scale distributed manufacturing"

If you have any questions