How to Manufacture Using the Amazon Model

Over the past decade, primary business models in almost every industry have shifted because of digitization. Leaders of the digital economy, including Google, Amazon, Microsoft, and Facebook, have leveraged this shift and used software systems to harness, evaluate and process data that have taken over economic leadership in the Platform Era. As a result, the total economic value of harnessing, processing, and sorting data has overtaken the production of goods – at least for now.

Agile Manufacturing: A New Method for Manufacturing

There has been a significant shift towards data-driven production in the past five years. For example, as the quality of industrial 3D printing improves and drives down prices, there has been a considerable move from producing prototypes to functional products, which is a landmark for product digitization. In addition, end products are produced on-demand using digital data. Just as the Amazon growth model illustrates, when customer data begins to influence process streams, it drives customization, automation, and entirely new business models.

While additive manufacturing has been a focal point for digital production, other systems (artificial intelligence for logistics, sensor-based tracking throughout production processes) contribute to the rapid changes we are experiencing. This combination of manufacturing and monitoring allows entire production streams to adapt dynamically to new production requests.

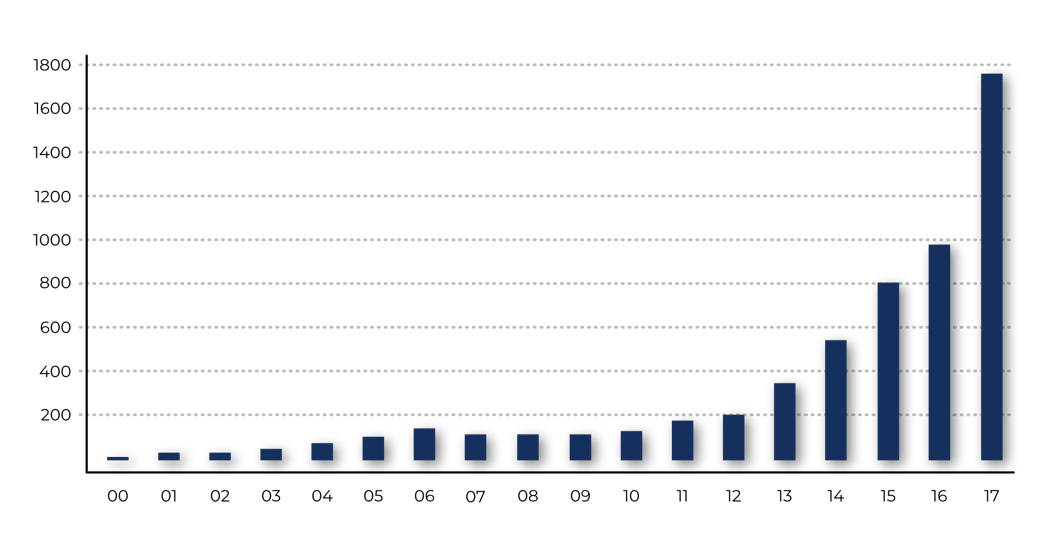

In the coming years, these trends will strengthen, as we’ve already seen AM production costs fall due to rapidly increasing amounts of new AM machines joining production capacity. (See graph below.) This effect will further be fostered by machines’ increase in efficiency and quality and the decrease in cost for tracking technologies and software platforms like 3YOURMIND, which combine automated access to production resources and customer data ready for generative design as well as intelligent logistics.

While the third and fourth industrial revolutions are already on their way and changing digital businesses, our production methods are not yet benefiting from digitization as much as they could. Today, additive manufacturing is still primarily stuck in the second industrial revolution of serial and mass production.

Agile manufacturing, or agile production (often simply “agile”), is a systematic method for increased flexibility-of-production capabilities within a manufacturing system that occurs without sacrificing productivity. While mass production and lean manufacturing focus on the continuous production of standardized products and the reduction of waste for, at best, mass-customized goods, agile – in sharp contrast – focuses on digitization methods to enable more flexible production capabilities.

This flexibility increase enables companies to act more customer-centric, as they can deliver product modifications throughout their whole lifecycle (or even truly customized products) with less time to market. To achieve this, companies use modern algorithms for data-driven intuitive product design and demand prediction and fully digital production methods that can produce where and when an object is needed. The result: streamlined processes, decreased costs, and shortened logistics chains. Thus, agile manufacturing is built on principles that are very similar to those that powered the growth model of internet businesses like Amazon.

Because of this, agile manufacturing has clear advantages for both efficiency and customer expectations. Its advantages include:

- Decreasing production, logistic, and storage costs

- Quicker delivery times

- Genuine product individualization (instead of today’s mass individualization)

Over the next 15 years, the companies that climb to the top of industrial production will integrate data with physical production.

Moving From Industry 1.0 to Industry 4.0

The societal shifts resulting from the first and second industrial revolutions are evident to every business. Still, the third and fourth revolutions are happening around us now and are far more challenging to see clearly.

In the 90s, lean manufacturing redefined production processes by emphasizing increasing efficiency by minimizing waste within a manufacturing system. For example, reducing unnecessary inventory, movements, and waiting time. By reducing these, lean manufacturing increases efficiency but does not necessarily change its cost structures.

On the other hand, the recent advances in digital manufacturing are much more likely to have a direct impact on a company’s cost structure because it reduces the variable costs of production. For example, simultaneous output in the same machine from multiple digital design files removes one of the highest costs and barriers to flexibility in production: machine tooling. In addition, with intelligent software solutions, the entire production planning and execution can be automated and thus significantly reduce the required labor costs for manufacturing. As another example, additive manufacturing can simplify complicated assemblies and remove or minimize the need to put the various parts together.

Industry 4.0 also enables digital information processing to address individual customer needs through algorithms and automation. This adaptation is comparable to the same shift that flipped the film and retail industries as characterized by the examples of Netflix and Amazon. Agile manufacturing is about making customer-specific products using generative design, data-driven logistics, and optimizing all stages of production with predictive algorithms. As a result, agile manufacturing reduces production, product development, and delivery costs. All decisions are based on data from product recommendations to logistic center planning.

Today, many use cases are still more expensive in additive than conventional manufacturing. These costs are primarily due to a lack of clarity in good business cases and the large amount of post-processing that needs to be performed on AM parts to prepare them for end-use. However, as technology matures, those factors are substantially reduced each year.

Leveraging Digital Production Streams

In 2006, Chis Anderson, then chief editor at Wired magazine, published The Long Tail. From his position among the pioneers of internet businesses in Silicon Valley, he was able to see a shift in the way consumers accessed products. Then, consumers had to take what was offered, with few products dominating each market. For example, the now-defunct Blockbuster movie store often stocked 50-200 copies of each ‘bestseller,’ a single copy of ‘second tier’ films, and well, that was more or less the depth of their movie catalog.

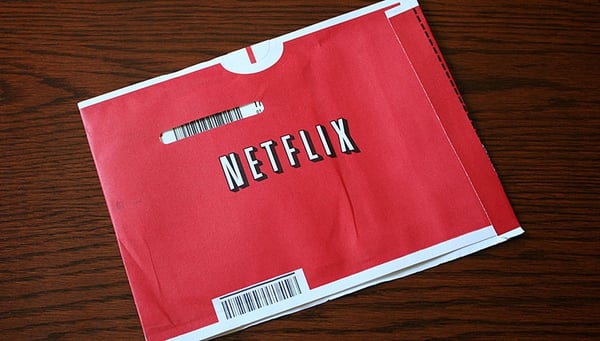

In 1997, Netflix entered the market. Their original business model was simple – choose movies on a website mail-ordered from massive warehouses of DVDs instead of movie stores. In a few short years, the new business model created a new customer expectation: access thousands of movies instead of hundreds. As their warehouses became more efficient, they rose to tens of thousands of titles. Yet there were still limits. Netflix had to predict customer demand using sophisticated algorithms (they still had lots of inventory devoted to ‘best sellers’). In addition, customers experienced limited accessibility due to the time it took to send a DVD through the mail and the number of DVDs allowed by their subscription size.

In 2007, Netflix began streaming video and fundamentally flipped the equation. With streaming representing the shift to film digitization, the cost to deliver a movie title to the end customer approached the cost of moving data. After paying licensing fees, movies were encoded and placed on the Netflix platforms, enabling consumers to view any film in their catalog at the same cost to Netflix. An individualized experience was the same price as a mass-produced experience.

Agile manufacturing promises to bring those same principles to products. An individualized product will not cost any more than a mass-produced item. Over time, once design and licensing fees recover, the cost of delivering a product to the end customer will approach the raw material cost. The generative design combined with digitally driven production and AI/robotics promises to enable 3D models dynamically designed based on customer and production specifications that are automatically added to production at the nearest production and logistics center.

Business Lessons From the 'Long Tail' of Production

When Blockbuster dominated video rental, 98% of what people viewed was mass-produced media. But as access and delivery costs approach zero, customers begin to dive into the 'Long Tail.' To illustrate, a fringe 1970s Kung-Fu movie may even end up being more lucrative for Netflix than a Hollywood blockbuster. Adding a kung-fu flick with cheaper licensing fees can begin being recommended to customers when they watch their first Bruce Lee movie. The predictive algorithms are specific to customer taste, so the unique one-offs will likely make more authentic fans in the process.

On-demand, individualized physical products are slowly becoming part of customers’ expectations. Just a few years ago, additive manufacturing could only deliver low-quality prototypes. Now we see customized accessories in cars, efficient engine parts for rockets, and the hearing aid market almost entirely switch to 3D printing.

But the expectations are already there. It is rare for buyers not to check through at least three pages of options on Amazon to read the customer reviews. The customer expects to get what they want, delivered when and where they want it.

Agile manufacturing uses data-driven processes to predict ordering and make recommendations that will begin to provide the products you need “before you know you want them.” This promise of Industry 4.0 will not only be brought into reality by agile manufacturing – it’s already on its way.

Can I See Agile Manufacturing Today?

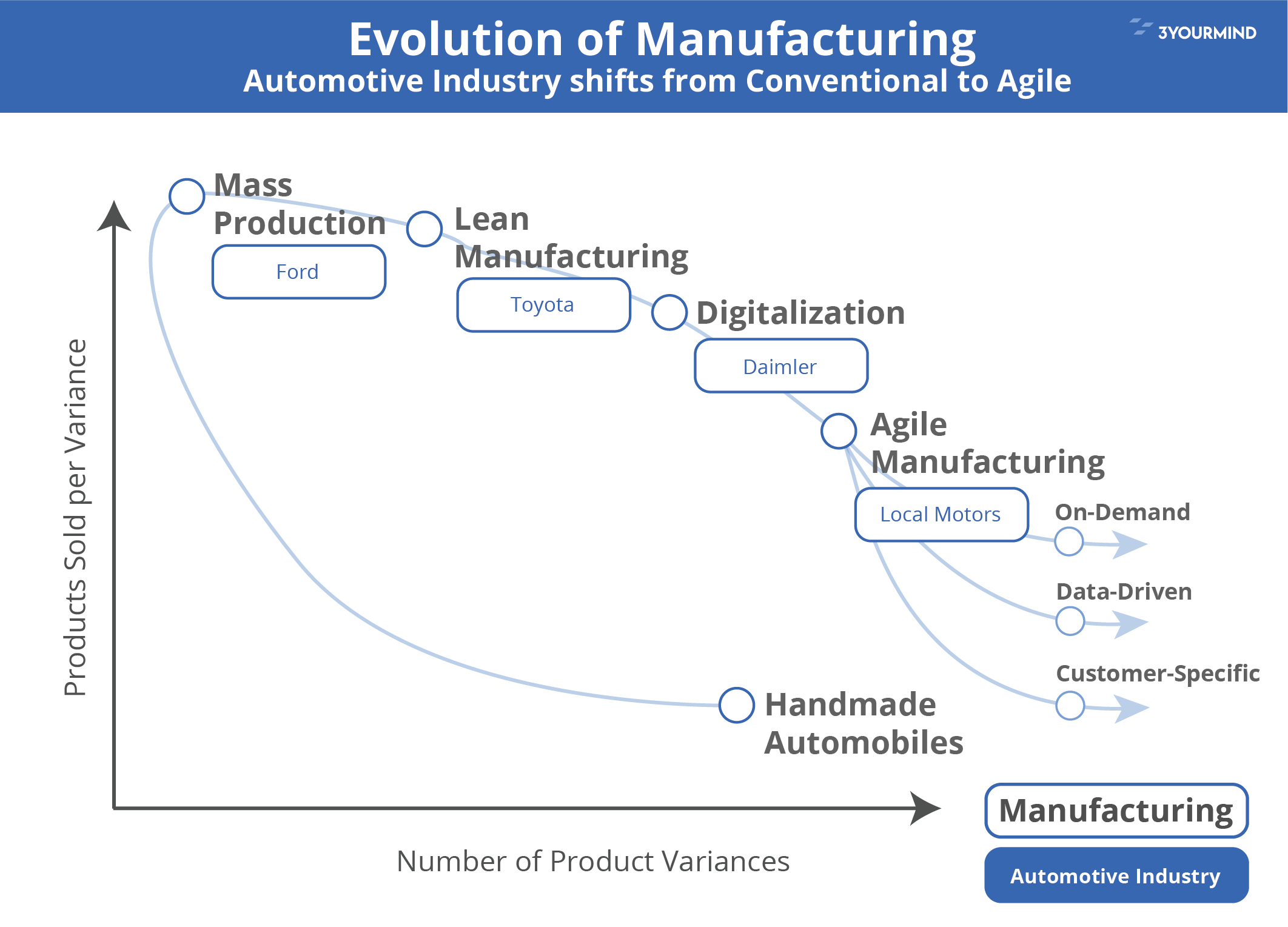

One industry that is already advancing towards agile manufacturing is the automotive industry. Ford transitioned manufacturing individual, hand-crafted vehicles in the 19th century to serial production in the early 20th century. After WWII, automotive mass production began with well-known examples like the VW Beetle. As the graph shows below, Toyota introduced lean manufacturing in the same century. As the speed of change continues to increase, the next revolution is on our doorstep.

With Local Motor Labs, we see a company that uses additive manufacturing to produce disruptive vehicles. Their in-house engineers no longer build designs for their cars but crowd-sourced to assure that the newly designed vehicles match the exact clients’ needs. Although such a fully automated design process is not representative of where we are today, the trend towards truly customized vehicles enabled by additive manufacturing processes is becoming increasingly evident.

At the same time, companies such as Daimler and EOS are collaborating to build a ‘Next Gen AM’ Factory which aims to enable fully automated production and post-processing for industrial-grade small serial production. This move demonstrates a willingness toward a new way to produce individual products – efficiently at a large scale.

Need more ways to streamline additive manufacturing operations? Learn how digital tools can help alleviate pain points.