Enable Consistent Part Quality for On-Demand Manufacturing

Learn how to clear part quality hurdles in additive manufacturing.

Consistent part quality is one of the most important hurdles to clear on the path to on-demand manufacturing. Standardization guidelines for individual parts have yet to be fully developed, and technology, part applications, and production operations have yet to fully mature to guarantee quality over prolonged production runs. However, organizations with additive manufacturing strategies can begin planning for future production capabilities by enabling documentation, data capture, and traceability.

Streamline Additive Manufacturing Workflows

The first step toward consistent part production is identifying opportunities to reduce human error. Equipping AM operators with tools and software solutions that reduce manual processes is the first step to ensuring order accuracy and maintaining consistent production environments.

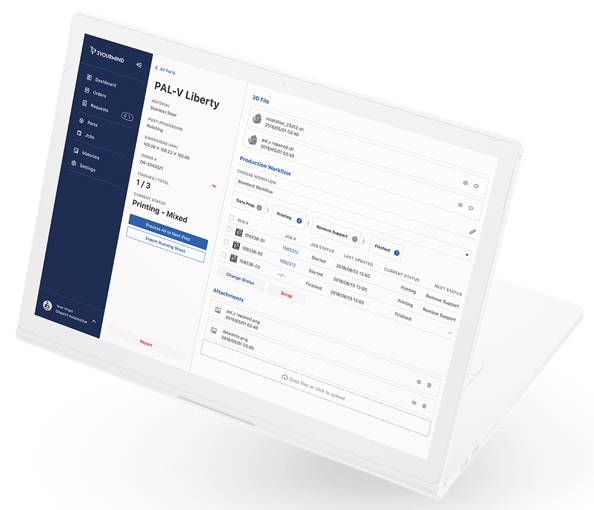

3YOURMIND’s Agile Manufacturing Execution Systems (MES) module helps automate processes for AM operators, including production scheduling, part tracking, and increasing availability of production and post-processing information at every workstation on the AM shop floor.

As a result of using Agile MES, AM production facilities experience up to 30% reduction in mistakes caused by human error, including failure to meet production capacity, quality oversight, scheduling conflicts, and other workflow inefficiencies, to improve on-time delivery.

Capture End-to-End Additive Manufacturing Data

The next major component to facilitate consistent part quality is identifying parameters for data capture. AM output quality can be significantly improved by collecting and delivering the right part data to the corresponding steps in the production chain.

For example, part requirement information such as materials used, technical specifications, and AM machine model are just a few possible data points collected via Agile MES’s part specifications feature.

By capturing data through a centralized platform, AM production facilities can accurately collect information to maintain rigorous documentation to reduce data silos and empower AM organizations to play an active role in their data ownership. As a result of solid data processes and storage guidelines, additive manufacturers can unlock part traceability.

Should a quality recall occur after a part has been produced, AM team members can drill down into the minutiae of part data, including parts that utilized specific material lot numbers, production temperatures, AM operators on-site during production, and more.

Do More With On-Demand Manufacturing

With a data-centered mindset on AM part quality, organizations utilizing AM strategies can develop the foundation necessary for enabling on-demand manufacturing. In addition, producing consistent parts expands the potential for on-demand manufacturing use cases, further unlocking savings to justify additive manufacturing investments.

Discover how customers like Erpro use workflow software to track AM quality control and production.