How Can 3D Print Service Providers Scale-Up Production?

Learn how 3D printing service providers can adopt workflow best practices to overcome challenges that make it difficult to scale up operations.

Today, service bureaus are facing a number of challenges that can make it difficult to scale up operations. For example, issues related to order intake, pricing, and client communication. However, these problems can be overcome by following some best practices and adopting more efficient solutions. This series of articles has advice for 3D printing service providers, showing ways in which to address these issues.

In the first article, found here, solutions for order intake, pricing and client communication were covered. Yet, these are not the only existing challenges. Service bureaus also often struggle to have an accurate overview of their production floor, leading to slower decision making, lower part quality, and therefore decreased productivity. This second article in the series will address how service bureaus can optimize production workflows in order to boost business. Here are some more tips and tricks for AM service providers, focusing especially on the benefits of implementing Additive MES software.

What are the challenges service bureaus face when it comes to production?

-

Ensuring quality

The first challenge for service bureaus is ensuring the quality of a customer’s part and making sure it meets their demands, no matter the sector of activity. However, there are a number of steps that bureaus must take to ensure that they are producing parts with the necessary quality.

First, service providers need to collect the data and part requirements directly from the customer, which can be a complex process.

For instance, if they are gathering this information from different people within the same company, or if the needs of the client are not clear. Not to mention, in the end it can be difficult not just to know who is giving the final information, but which source should in fact be trusted for the final design.

This is only compounded by the fact that internal vocabulary for different processes, etc., used by a service provider can differ from the vocabulary used by the customer, further inhibiting comprehension of their needs.

This information must then be transferred to the shop floor. Problems can also arise in this next step, especially if the users have provided many different requirements or data which may not all be in one place.

Furthermore, the more people involved, the greater the possibility that the message will be compromised or poorly communicated, leading to misunderstandings surrounding the needs for the part.

Finally, they must put in time to validate the quality of the parts before they can be given to the customer. If any faults are found then that will also cause the providers to waste both time and materials (and thus money) in order to remake it.

-

Control the production flow in real time

Going off the idea of ensuring part quality, controlling the production flow in real time can also be a significant challenge for service bureaus. Especially if they have many different machines and orders to manage.

For example, many service bureaus are still manually scheduling production parts using paper or boards. However papers are easy to lose which can cause delays.

Moreover, they do not offer an overview of the entirety of production, making prioritization of jobs difficult. As a result, a part that may need more time could be started later than optimal, while a part that might not take as long gets priority.

Adding to these issues, many 3D printing service bureaus also struggle with managing and tracking production schedules in real time, potentially resulting in missed projects. These problems only get larger as service providers add more machines and customers, posing a significant barrier to scaling up production and gaining more customers.

Furthermore, the lack of control of production flow has a direct impact on results and ROI. For example, not being able to draw conclusions related to production or predict future orders. It would also be impossible to effectively plan maintenance for machines.

Addressing these problems is the first step that any 3D printing service provider must take before they can hope to scale up their business.

2. Role of a Manufacturing Execution System (MES) in production optimization

To address these challenges, AM service providers should invest in additive MES software.

These software are designed to accompany users from the beginning to the end of part production, minimizing errors and part failures alike and, as such, are key to unlocking production efficiency.

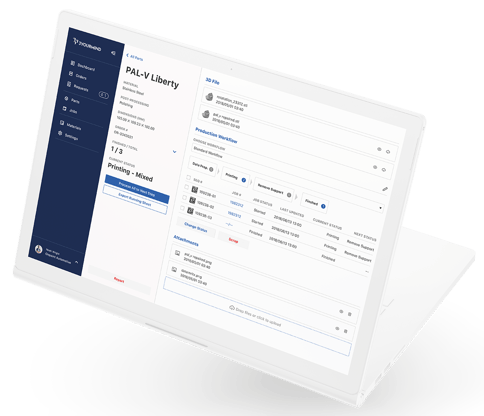

The Agile MES (Manufacturing Execution System) with machine connectivity from 3YOURMIND is the ideal solution.

This online tool guides a team to select the best production recommendation for each part that is uploaded.

But what characteristics make it so suitable?

-

Agile MES ensures quality through traceability and repeatability

One way Agile MES can help service providers is by ensuring quality with traceability and repeatability. Both of which are critical when it comes to managing large numbers of orders and parts.

This can be done as follows:

- Track Units from Order to Finished Part

Tracking units from order all the way to the finished part ensures data consistency between ordering and production. This in turn helps to reduce communication time and improve production accuracy.

- Assure Quality with traceability

Actions taken are tracked in a history with timestamp and the user's name who made the update for digital quality assurance documentation not just significantly saving time but also increasing transparency and reassuring clients.

- Collect Data Directly using Machine Connectivity

Finally, when it comes to quality assurance, 3YOURMIND is building machine connectivity with leading vendors for real-time production tracking and storage of key metrics for quality control. This programming only needs to be done once, the software will then collect data ensuring that service providers do not need to do it again.

This will save them a significant amount of time, reduce the risk of errors and offer more repeatability.

-

Manage, plan and track production in real time

The next solution addresses how service providers can control their production flow in real time. Namely, with the Agile MES from 3YOURMIND, it is possible to automate planning, scheduling and tracking of the production floor all in one easy-to-use solution.

This automation takes place in a number of ways.

- Use Software to Prioritize Parts

Meeting delivery dates and optimizing machine utilization are key profit metrics for service providers. The Agile MES is capable of recommending jobs for efficient production, enabling service bureaus to reap benefits especially in terms of ROI.

- Agile Rescheduling when Production Changes

Scheduling is also important, especially when it comes to a scaled up business. More concretely, using the Agile MES’ digital schedule allows jobs and parts to be instantly shifted, updating worklists and production sheets across all locations. This saves time and increases efficiency by putting important information all in one place.

- Instantly Generate Production Sheets

Furthermore, with this software, it is possible to generate downloadable production sheets from the real-time schedules to use in manual or digital production floor workflows.

- Machine Connectivity

Additionally, 3YOURMIND’s digital thread covers the entire production process by pushing machine data to the Agile MES platform through the IIoT (Industrial Internet of Things) communication platform to collect, map and translate machine data.

Meaning that in real time all data is in one agile platform, allowing for better visibility and traceability. This platform enables distributed manufacturing, making it possible to monitor large production facilities at multiple sites from a single source. Which in turn creates transparency across the global process landscape. Through this, users can identify potential ways to either save time or to minimize the risk of errors early in the process, allowing them to quickly react through real-time insights in the worldwide production network by leveraging data analytics.

- Optimize Production Efficiency with AM Analytics

Finally, Agile MES also includes analytics of KPI metrics to optimize production and machine utilization for all linked production locations.

3. Unlock production management with full benefits

So what exactly are the benefits?

First, it is important to note that by combining with other additive software, especially the 3YOURMIND Agile ERP (see all features in the first article here), users would see even more advantages, helping service bureaus to effectively scale up their business and stand out in an ever-expanding field.

In combining Agile ERP and MES by 3YOURMIND, like SPECTROPLAST and ZIGGZAGG, it is easier to define part requirements during ordering, thus saving hours tracking down information later.

Additionally, service bureaus have access to custom forms that allow them to gather necessary production data. This feature is built into the platform, ultimately creating a smoother workflow.

Using the Agile ERP + MES is a truly winning combination.

And the figures speak for themselves, AM Service Bureaus that use 3YOURMIND’ s Agile ERP can benefit from:

- Reduction of 75% of the manual work time

- Full process automation with up to 100% data transparency

- Double the number of your customers and orders without additional staff thanks to online business and instant quotes

- Up to 100% customer satisfaction and trust to convert them into ambassadors

And with Agile MES

- Increase machine utilization by 130-150% with our smart scheduling tools, saving hundreds of thousands of euros per year.

- Fully automate workflow to reduce errors by up to 30%

- Increase efficiency and on-time delivery.

Conclusion

To be well-prepared for anything the future might bring, it makes sense to digitize, automate and standardize processes. A software suite like that from 3YOURMIND will help to do this.

By combining the Agile MES and the Agile ERP, service providers can fully automate and control their workflow from start to finish, resulting not just in better quality assurance and more efficient production flow, but in saved time and money.

For anyone looking to truly scale up their operations, and even more importantly to increase customer base, investing in this software is key.

Book a demo and skyrocket your business with Agile MES