How Advanced Manufacturing Technology Supports Supply Chains

Discover how advanced manufacturing technologies support supply chain resilience by enabling new cutting-edge production processes.

For enterprise companies providing critical goods or services, the supply chain is a topic that is consistently top-of-mind. Though, for many years, globalized supply chains have proved useful for slashing procurement prices, they've also made apparent the frailty of supply chains to environmental, geopolitical, and market disturbances. Several years have passed since COVID-19 revealed the scope of supply chain weaknesses, many of which have since stabilized; nevertheless, governments and enterprises are searching for opportunities to restore manufacturing or, at least, bring manufacturing capabilities closer to their point of need.

That said, it's hard to justify localized manufacturing using traditional methods on a broad scale—the unit economics aren't competitive compared to the margins that globalized manufacturing offers. However, advanced manufacturing technologies provide opportunities for enterprise organizations to develop new production paradigms that address modern procurement pain points while mindful of cost considerations.

In this article, we'll discuss different ways advanced manufacturing technologies are used to support supply chain and logistics operations.

What is Advanced Manufacturing Technology?

Advanced manufacturing technology isn't just one thing; it encompasses a range of innovative processes, tools, and systems designed to optimize manufacturing operations, enhance productivity, and improve product quality. These technologies include automation, robotics, additive manufacturing (such as 3D printing), artificial intelligence (AI), data analytics, and supply chain digitization.

Using these technologies enables companies to streamline production processes, reduce lead times, customize products, and respond quickly to market demands, ultimately driving efficiency and competitiveness in the manufacturing industry.

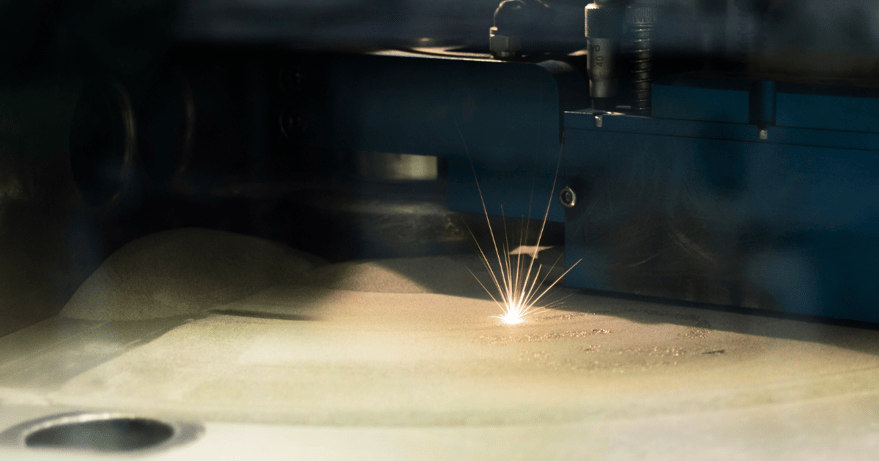

Metal selective laser sintering (SLS) is an advanced manufacturing method that enables companies to produce metal parts on demand.

How to Reinforce Supply Chains Using Advanced Manufacturing Technology

There are several advanced manufacturing technologies, but how can enterprises use them synergistically to strengthen supply chains?

First, it's critical to define the current problem and the end goal. For example, many enterprise companies struggle to procure the parts they need to maintain operations. The problem is that many suppliers that originally produced the parts they needed to operate equipment are no longer available, so they must find alternative solutions.

For this reason, additive manufacturing is often looked to because it can produce points at the point of need. Indeed, additive manufacturing can produce metal and polymer parts that perform equal to, if not better than, their traditionally manufactured counterparts. However, to compete against parts procured in the existing supply chain, parts produced with additive manufacturing need to rival the cost or, at the very least, the value of the part.

For example, Siemens reports that a single hour of operational downtime can cost upwards of $500,000. This is a business case where additive manufacturing shines. For those slow-moving, difficult-to-procure parts, additive manufacturing provides value in terms of time saved in production lead time and the revenue saved by reducing downtime.

So, how can companies use advanced manufacturing technologies to make these kinds of savings with additive manufacturing possible?

It starts by understanding the full scope of the part value chain.

Know What's Hiding In Plain Sight Within Your Data

Many enterprise companies today have thousands, if not tens of thousands, of parts in their inventory. A quantity that, even with a team of engineers equipped with advanced additive manufacturing knowledge, would require years of sifting through individual parts to find the golden nuggets.

Advanced manufacturing software, like 3YOURMIND's part screening and business case solution, can analyze 2D part drawings, 3D part files, and data points to assess the cost and technical feasibility required to produce a part with additive manufacturing.

This streamlined capability can have a profound impact on enterprise organizations. By knowing specifically which parts can be printed with additive manufacturing and which parts should be printed from an economic standpoint, organizations can create a short list of parts they can focus on to optimize and digitize for 3D printing.

Watch the video below to learn how you can quickly assess parts to determine if they make strong use cases for additive manufacturing:

Digitize Parts So That They Can Be Produced Anywhere

Digitizing parts is a crucial move that can help enterprise organizations have greater autonomy over the procurement and production of the parts that they use every day.Digitizing a part for additive manufacturing involves creating a digital representation of the physical object using various scanning technologies, such as 3D scanning or Computer-Aided Design (CAD) software. This digital model captures the geometric dimensions and surface details of the part with precision.

Once digitized, the model can be manipulated, optimized, and prepared for additive manufacturing processes, such as 3D printing. This preparation may include refining the design for manufacturability, optimizing support structures, and slicing the model into layers suitable for additive manufacturing. Digitizing parts streamlines the transition from concept to production, facilitating rapid prototyping, customization, and on-demand manufacturing.

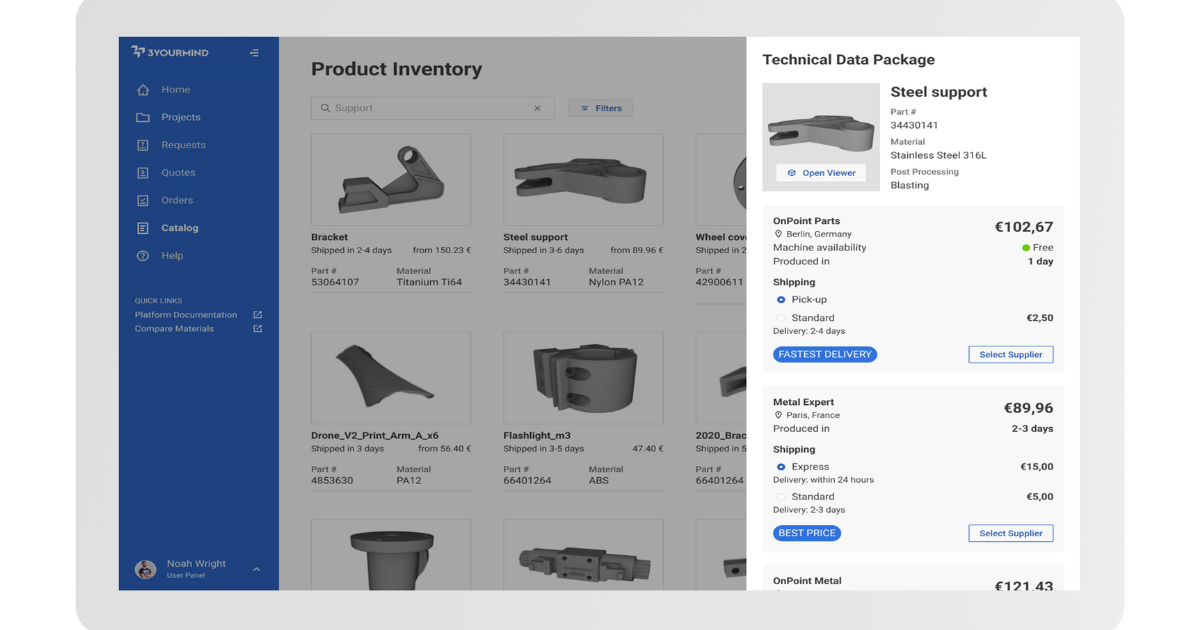

Use 3YOURMIND to digitize parts for 3D printing and safely and securely order them directly from suppliers.

3YOURMIND's digital inventory interface allows enterprise companies to create libraries of digital part files. With these libraries (or digital inventories, as we call them), companies can start managing their inventory virtually, limiting the need to maintain vast stocking units of slow-moving costs. By producing parts in-house or via an approved supplier just in time, enterprise companies free up valuable capital tied into warehousing parts while having parts readily available to mitigate revenue loss from operational downtime.

Read more: Discover how this energy equipment supplier uses 3YOURMIND to build digital inventories for Petronas.

Print Parts On-Demand With Additive Manufacturing

Once you've identified your parts for additive manufacturing and digitized them, it's time to start printing.Additive manufacturing brings significant supply chain benefits by enabling on-demand parts production with reduced lead times and inventory costs. By eliminating the need for traditional manufacturing processes like tooling and molding, additive manufacturing streamlines production workflows and enhances agility within supply chains.

Moreover, localized production capabilities allow for shorter transportation routes, minimizing carbon emissions and enhancing responsiveness to market demands. With additive manufacturing, companies can optimize their supply chains by producing customized parts efficiently, accelerating innovation, and maintaining competitive advantages in dynamic market environments.

Download these customer use cases to learn how companies across different industries save time and money by producing parts with additive manufacturing.

Leverage Robotics for Post-Processing to Produce Consistent Parts

Using robotics for post-processing in additive manufacturing can significantly enhance the consistency of produced parts. Robots can execute repetitive tasks with precision and uniformity, ensuring consistent surface finishes, dimensional accuracy, and quality across all manufactured parts. Unlike manual post-processing methods, which are prone to variations in technique and human error, robotics offer reliability and repeatability. By automating post-processing tasks such as sanding, polishing, or deburring, robots can achieve consistent results, improving part quality and reliability.

Additionally, robotics can extend engineers' impact by enabling them to focus their efforts on activities that require their expertise, such as optimizing parts for additive manufacturing. As such, using robotics in post-processing can further reduce production lead times and increase production efficiency.

Overall, integrating robotics into post-processing workflows enhances the consistency and quality of parts produced through additive manufacturing, making them more reliable for various industrial applications.

Advanced Manufacturing Technologies Support Strong Supply Chains

Advanced manufacturing technologies represent the cornerstone of securing resilient and adaptable supply chains for the future. With the increasing complexities and uncertainties in global markets, these technologies offer unparalleled capabilities to enhance efficiency, flexibility, and responsiveness within supply chain operations.

From automation and additive manufacturing to data analytics and supply chain digitization, these innovations empower companies to optimize their production processes, reduce lead times, and mitigate risks effectively. Embracing advanced manufacturing technologies isn't just about staying competitive; it's about building agile and robust supply chains capable of confidently and successfully navigating the challenges of tomorrow's dynamic landscape.

Contact us to learn how 3YOURMIND software streamlines advanced manufacturing activities to strengthen supply chains.