Increase Production Rates for On-Demand Manufacturing

Find out why increasing the production rate is essential to enable on-demand manufacturing.

Additive manufacturing (AM) can be a numbers game. Low-volume production of AM parts is costly for on-demand applications – the higher your AM costs, the fewer savings you’ll achieve from using AM versus conventional manufacturing – regardless of its supply chain and warehousing benefits.

Source: Fraunhofer surveys and interviews, World Economic Forum

According to industry survey results in a recent report by the World Economic Forum, the desire to enable mass customization, serial production, small-scale production, aftersales, and pre-serial production use cases fuel future AM market growth.

To achieve these goals, however, increasing the production rate is necessary to distribute the cost of machine depreciation across a larger number of parts. Unfortunately, many organizations do not have the organizational processes to increase production rates.

Therefore, before embarking on an on-demand manufacturing journey, it’s essential to prioritize production workflows.

Streamline Pre-Production Processes

Organizations manage several pre-production processes before an order makes it to the AM shop floor, which can have costly effects on time and labor resources if they’re not optimized.

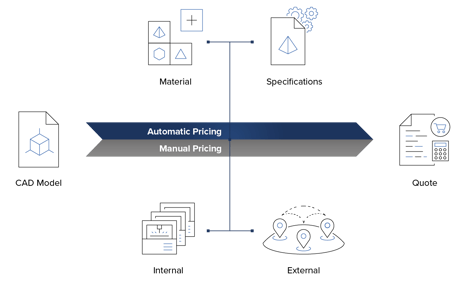

For example, configuring price quotes using laborious part calculation methods can be time-consuming, often requiring several calculations based on part material, print specifications, and more. Although the typical inclination is to hire more people to help manage processes, the shortage of knowledgeable AM workers can make this challenging.

Agile ERP uses custom pricing formulas to create automatic price quotes.

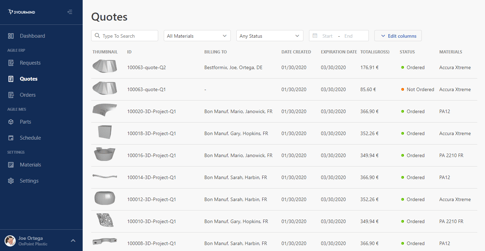

Instead, implementing 3YOURMIND’s Digital Inventory Management software can alleviate pain points associated with increasing order volume.

As a result of using 3YOURMIND, additive manufacturing firms can:

- Reduce manual processes by 75%

- Experience 100% data transparency with entire process automation

- Double order quantities with no additional staff

- Increase customer satisfaction by up to 100% to help convert clients into AM ambassadors

3YOURMIND also automates price calculations using a custom-built algorithm to empower customers to browse different price configurations, review previous job pricing through a digital catalog, and take ownership of purchasing decisions. Internally, automatic pricing simplifies ordering steps for AM workers to increase order processing timelines and reduce manual errors.

Watch: Erpro’s 3D Factory uses 3YOURMIND to produce millions of mascara brushes for Chanel.

Address Communication Challenges

Despite all of the methods we have to communicate with each other, including e-mail, call, text, and video conferencing, communication can be challenging if it’s too distributed.

For example, customer-facing employees juggling multiple project orders may face difficulties coordinating project changes using methods like e-mail and can quickly lose time waiting for critical responses for production. Therefore, communication must be centralized within work processes to increase output by connecting customers, account executives, and AM operators throughout the production process.

3YOURMIND's in-platform communication makes information sharing easier.

3YOURMIND’s Agile ERP and Agile Machine Execution Systems (MES) solutions simplify this process through in-platform communication that permits customers to share notes, descriptions, or changes to specific part jobs.

This cross-module support helps alleviate order intake pain points while creating traceable documentation for increased order insight. In addition, customers and production team members receive automatic updates, including received orders, job status, and final delivery, so all parties have a clear timeline of each print job without requiring additional communication efforts.

Optimize Machine Utilization With Production Quality Management

On-demand manufacturing unlocks exciting production opportunities, but on-demand initiatives will likely underachieve without optimized machine utilization.

By maximizing machine utilization, AM production facilities get the greatest output possible for each production run, to produce more parts, for more orders, faster and easier than ever before.

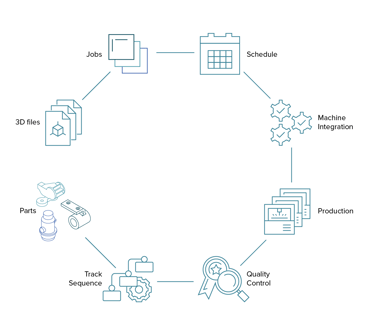

3YOURMIND’s Production Quality Management solution links the entire production workflow, from the original 3D file to part production, unlocking efficiency and new opportunities for optimized processes.

With Agile MES, our customers have successfully

- Increased machine utilization by 130-150% with intelligent scheduling tools,

- Resulting in hundreds of thousands of dollars in savings per year.

Here’s how:

3YOURMIND supports additive manufacturers throughout the production journey.

Custom AM workflows match the way your company schedules and assign AM jobs.

You can lay out each production scenario within the Agile MES to match your precise production and post-processing workflows. Those processes become the basis of scheduling while routing through various machines and workstations.

All progress is then tracked in the workflow to make better work estimations and help you maintain accurate delivery times.

-

Intelligent part prioritization recommends efficient job scheduling.

Your scheduling team can generate job build lists based on material, delivery date, and priority level to create their jobs quickly, without digging through orders and data. It’s never been easier to maintain your delivery schedule.

-

Production planning gives an accurate overview of the production floor.

Your team can quickly edit jobs to meet project deadlines and accurately plan by using print run estimations and scheduled downtime. All job orders for machines, post-processing, and coordination are in a single, clear overview.

-

Sequence tracking monitors each part’s status to increase transparency.

Each unit produced is tracked to keep a clear view of the production floor. Seeing the progress of all elements of an order also helps guarantee delivery times. The part progress can be viewed by anyone with access to the user interface, and this documentation leaves a clear, auditable pathway for quality control.

Software for the Future of On-Demand Additive Manufacturing

Set the tempo for the future of on-demand additive manufacturing through intuitive workflows and continuous data streams by using 3YOURMIND’s On-Demand Manufacturing Platform. With greater efficiency and an increased production rate, on-demand manufacturing becomes more feasible and results in a greater return on investment.

Connect your AM shop floor! Learn how 3YOURMIND enables machine connectivity for on-demand manufacturing.