Is Your Business Ready for Industrial 3D Printing? Here's How to Tell

In recent years, industrial 3D printing has emerged as a transformative technology, revolutionizing manufacturing processes across various sectors. From aerospace and automotive to healthcare and consumer goods, businesses increasingly turn to additive manufacturing to streamline production, enhance product design, and drive innovation.

However, adopting industrial 3D printing isn't a one-size-fits-all solution. Determining whether your business is ready to embrace this technology requires careful consideration of several factors.

What is Industrial 3D Printing?

Industrial 3D printing, also known as additive manufacturing, refers to the process of creating three-dimensional objects by adding material layer by layer based on a digital design. Unlike traditional manufacturing methods that often involve subtracting material through processes like cutting or drilling, 3D printing builds up material, producing complex shapes and structures with precision.

Industrial 3D printing, as the name suggests, also distinguishes itself as a method to produce 3D-printed parts at an industrial scale. Compared to maker or hobbyist 3D printing, industrial 3D printing leverages more complex machine technology to render 3D printed parts using various production methods, including SLM, stereolithography, FDM, and powderbed fusion, among others. These advanced production technologies also utilize high-performance materials, such as metals, polymers, and carbon fiber, to be able to withstand the often harsh environments required in industrial environments.

Industrial 3D printing offers enterprise companies the opportunity to modernize spare part procurement and digitize new and existing parts so that they can be produced on demand and closer to the point of need.

But how do you know if your company or industry is suited for industrial 3D printing?

In this article, we'll discuss seven important factors companies should consider before going 'all in' on industrial 3D printing.

1. Understanding Your Production Needs:

Before diving into industrial 3D printing, it's essential to evaluate your production requirements. Consider the complexity, customization, and volume of your products.

Are you producing highly intricate components or prototypes that demand rapid iteration? Industrial 3D printing excels in scenarios where traditional manufacturing methods fall short, offering unparalleled design freedom and scalability.

3D printing can be a valuable method for producing both simple parts and parts with complex geometries on-demand.

3D printing can be a valuable method for producing both simple parts and parts with complex geometries on-demand.

2. Assessing Material Compatibility:

Industrial 3D printing encompasses many materials, including plastics, metals, ceramics, and composites. Evaluate whether the materials compatible with additive manufacturing meet your product specifications and performance standards.

Advancements in material science have expanded the capabilities of 3D printing, enabling the production of durable, high-quality parts suitable for diverse applications.

Want to learn more about material compatibility? Learn how Arkema's Easy3D platform makes it simple to select the best material for your part.

3. Cost-Benefit Analysis:

While industrial 3D printing offers numerous advantages, including reduced lead times, minimal material waste, and enhanced product customization, it's essential to weigh the costs against the benefits. Evaluate the initial investment in equipment, materials, and training, as well as the long-term savings derived from shorter production lead time, fewer warehousing costs, and less operational downtime.

Learn how much you can save in warehousing and manufacturing costs with 3YOURMIND.

4. Infrastructure and Expertise:

Implementing industrial 3D printing requires more than acquiring the necessary hardware and software. Assess whether your business has the infrastructure and expertise to support additive manufacturing operations effectively. This includes skilled personnel capable of designing for 3D printing, maintaining equipment, and optimizing workflows to maximize efficiency.Investing in training and development programs can help bridge knowledge gaps and ensure a smooth transition to additive manufacturing.

5. Regulatory and Quality Compliance:

Depending on your industry, compliance with regulatory standards and quality assurance protocols is paramount. Ensure the materials, processes, and finished products meet regulatory requirements and industry certifications. Establish robust quality control measures to validate the integrity and performance of 3D-printed components and mitigate any potential risks.

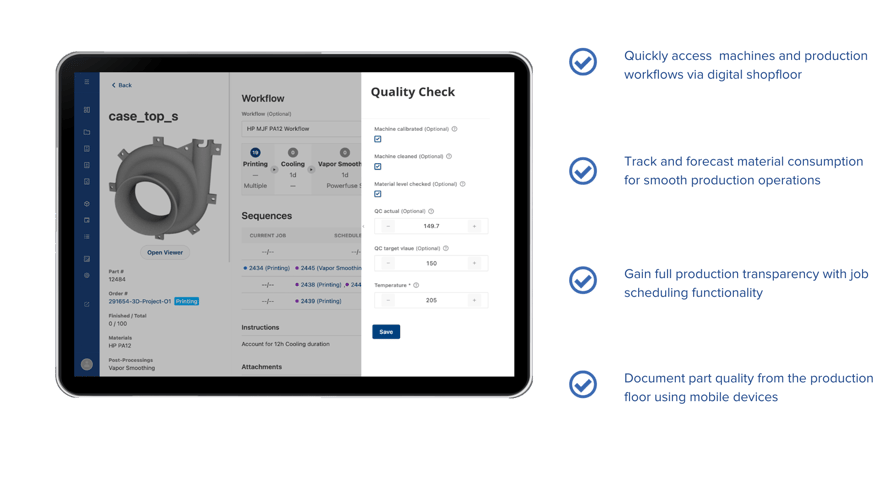

3YOURMIND offers tools to produce consistent, replicable 3D-printed parts.

6. Scalability and Future Growth:

Consider the scalability of industrial 3D printing within your business operations. Evaluate whether the technology can accommodate fluctuations in demand and support future growth initiatives. Assess the flexibility to adapt to evolving market trends and technological advancements, ensuring that your investment in additive manufacturing remains relevant and sustainable in the long run.7. Assessing Competitive Advantage:

Finally, consider how industrial 3D printing can confer a competitive advantage to your business. Explore how the technology enables you to enhance performance, accelerate time-to-market, and innovate in ways that were previously unattainable. Stay abreast of industry trends and competitors' adoption of additive manufacturing to capitalize on emerging opportunities and maintain a competitive edge.

Accelerate Your Industrial 3D Printing Journey With 3YOURMIND

3YOURMIND gives enterprise organizations the tools to modernize their industrial 3D printing workflow. 3YOURMIND starts by analyzing your organization's data and part files for value-adding 3D-printed part candidates. Our advanced algorithms evaluate your data to determine both the economic and technical feasibility to produce your parts with industrial 3D printing, saving you time by focusing only on the parts that matter.

Here's how it works:

Want to learn how 3YOURMIND can help your business scale its industrial 3D printing? Get in touch!