Which is Better? Traditional vs. On-Demand Manufacturing

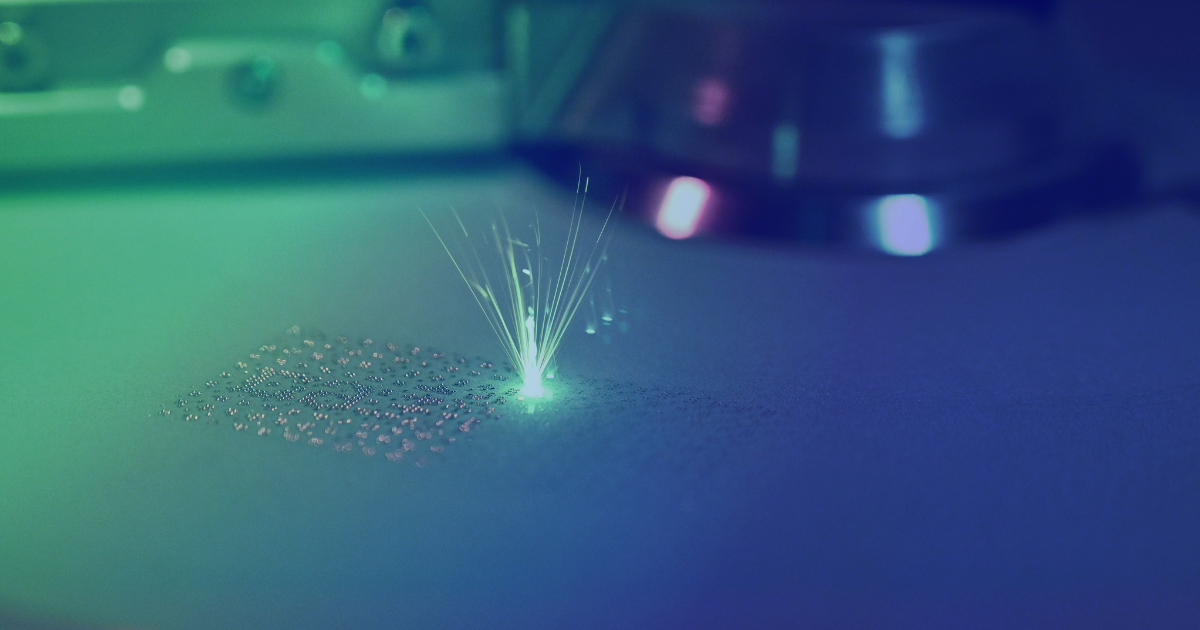

More and more major industries are adopting 3D printing technology. In this article, we'll weigh the benefits of traditional vs. on-demand manufacturing.

As an engineer, you are often faced with the critical decision of selecting the most suitable manufacturing method for your projects. Two prominent options that have gained significant attention in recent years are traditional manufacturing and on-demand manufacturing.

In this article, we will delve into a comparative analysis of these two approaches, exploring their strengths, limitations, and factors to consider when selecting which method to pursue.

Advantages of Traditional Manufacturing:

Traditional manufacturing encompasses well-established processes that have been refined over time. It includes methods such as casting, machining, molding, and assembly. This approach offers several advantages:

Reliability and Established Processes:

Traditional manufacturing techniques have a long-standing history and proven track record. The processes involved are widely understood, leading to reliable and consistent results.

High Production Volume:

Traditional manufacturing methods are often optimized for mass production, making them suitable for large-scale manufacturing with high output requirements.

Material Selection:

Traditional manufacturing provides access to various materials, including metals, plastics, composites, and more. This flexibility allows engineers to choose materials based on desired properties and specifications.

Advantages of On-Demand Manufacturing:

On-demand manufacturing, also known as decentralized or distributed manufacturing, leverages digital technologies to produce goods in response to specific customer needs. This approach offers several advantages:

Customization and Personalization:

On-demand manufacturing enables the production of customized and personalized products tailored to individual customer requirements. This level of customization can be beneficial in industries such as healthcare, fashion, and consumer goods.

Reduced Lead Times:

By utilizing digital manufacturing technologies like 3D printing, on-demand manufacturing significantly reduces lead times compared to traditional manufacturing. This allows for faster product iterations, rapid prototyping, and accelerated time to market.

Lower Inventory Costs:

On-demand manufacturing minimizes the need for large-scale inventory storage, as products are manufactured as needed. This reduces costs associated with warehousing, inventory management, and obsolescence.

Factors to Consider: Traditional vs. On-Demand Manufacturing

When deciding between traditional manufacturing and on-demand manufacturing, several factors should be taken into account:

Production Volume:

Traditional manufacturing is typically more efficient and cost-effective for high-volume production, while on-demand manufacturing is better suited for low to medium-production volumes or personalized products.

Design Complexity:

On-demand manufacturing excels in producing intricate designs and complex geometries that may be challenging or impractical with traditional methods. Traditional manufacturing may be preferred for simpler designs with well-established manufacturing processes.

Time Constraints:

If time-to-market is critical, on-demand manufacturing's rapid prototyping capabilities and reduced lead times can provide a significant advantage over traditional manufacturing.

Cost Considerations:

Due to economies of scale, traditional manufacturing may offer more cost-effective solutions for high-volume production. In contrast, on-demand manufacturing can be cost-efficient for low-volume production or customized products.

Are You Well-Positioned for the Next Era of Manufacturing?

Choosing between traditional manufacturing and on-demand manufacturing depends on various factors specific to your project requirements. While traditional manufacturing offers reliability, established processes, and high production volume capabilities, on-demand manufacturing provides customization, faster iterations, reduced lead times, and lower inventory costs.

In many cases, a hybrid approach combining traditional and on-demand manufacturing elements can be employed to leverage the advantages of each method. The key lies in carefully evaluating factors such as production volume, design complexity, time constraints, and cost considerations. As an engineer, staying updated on the latest advancements in traditional and on-demand manufacturing techniques will equip you with the knowledge and expertise necessary to make informed decisions.

Remember, the right manufacturing method will ultimately depend on your project's unique needs and goals. By leveraging the strengths of each approach and aligning them with your specific requirements, you can optimize your manufacturing processes and achieve desired outcomes.

Find out how 3YOURMIND can simplify your manufacturing decision-making by scanning your existing part inventories to identify the best business cases for on-demand manufacturing.