FAQs: Part Screening for On-Demand Manufacturing

In this article, VP of Product Stephan Galozy, answers questions about 3YOURMIND's part screening and business case functionalities.

What is Part Screening and Business Case?

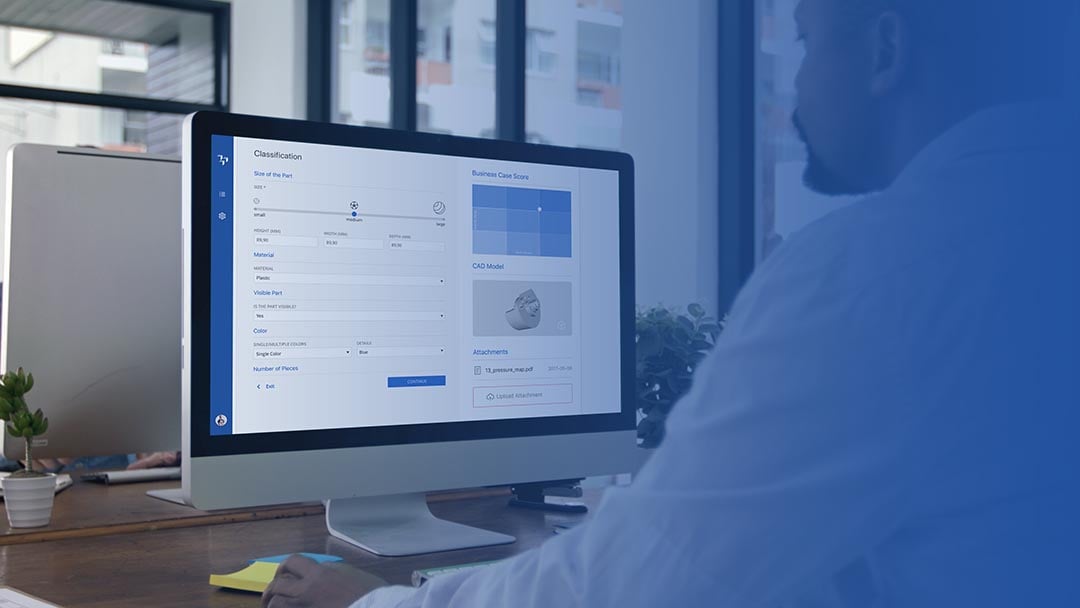

3YOURMIND’s Part Screening and Business Case solution help enterprises analyze their part inventory for on-demand manufacturing use cases. This solution enables part analysis through a top-to-bottom inventory analysis and a bottom-up use-case screening.

During this process, Part Screening and Business Case analyzes part data, scans for on-demand printability, and provides a technical and economic score to help determine whether a part is cost-effective using 3D printing technology.

As a result, enterprises can create a digital inventory of on-demand parts connected to 3YOURMIND’s comprehensive on-demand manufacturing platform to manage on-demand manufacturing job orders and production schedules. Using 3YOURMIND's qualification, digital inventory, and production quality management functionalities creates an end-to-end information stream for enterprises to evaluate and manage their on-demand manufacturing data.

How can my company be ready for on-demand manufacturing?

Before a part can be printed, you need to know which parts in your inventory are suitable to print. Companies mature for on-demand manufacturing can demonstrate suitable business use cases for producing parts on demand. However, this process is traditionally time-consuming and relies on the knowledge and availability of additive manufacturing (AM) application engineers to identify suitable parts.

3YOURMIND’s on-demand manufacturing software is a scalable solution to screen thousands of parts with less effort from experts. The software helps to simplify the part identification process by analyzing inventory data in minutes. As a result, enterprises can save up to 80% of the time normally required to identify parts.

How does 3YOURMIND analyze suitable parts for on-demand manufacturing?

First, 3YOURMIND evaluates the part for economic value to determine whether a part is cost-effective to print.

At the same time, the part undergoes a technical assessment to evaluate if the part can be printed using on-demand manufacturing. 3YOURMIND screens multiple technologies in parallel and gives advice on which is suitable. If the component demonstrates technical and economic value, the part can be prioritized for further technical evaluation by AM engineers.

What if my data quality isn’t great?

We have experience with data management for spare parts and can offer guidance to develop data management best practices within your company.

What type of file uploads does 3YOURMIND support?

3YOURMIND supports STL, STEP, .3MF, .zip, and CAD files, among many other file formats.

How many files can I upload to 3YOURMIND at a time?

Our part screening and business case solution can support bulk imports, enabling you to analyze part data more quickly and with fewer delays.

What if I don’t have 3D files?

That's ok; we don't need it! We can process metadata to evaluate on-demand suitability.

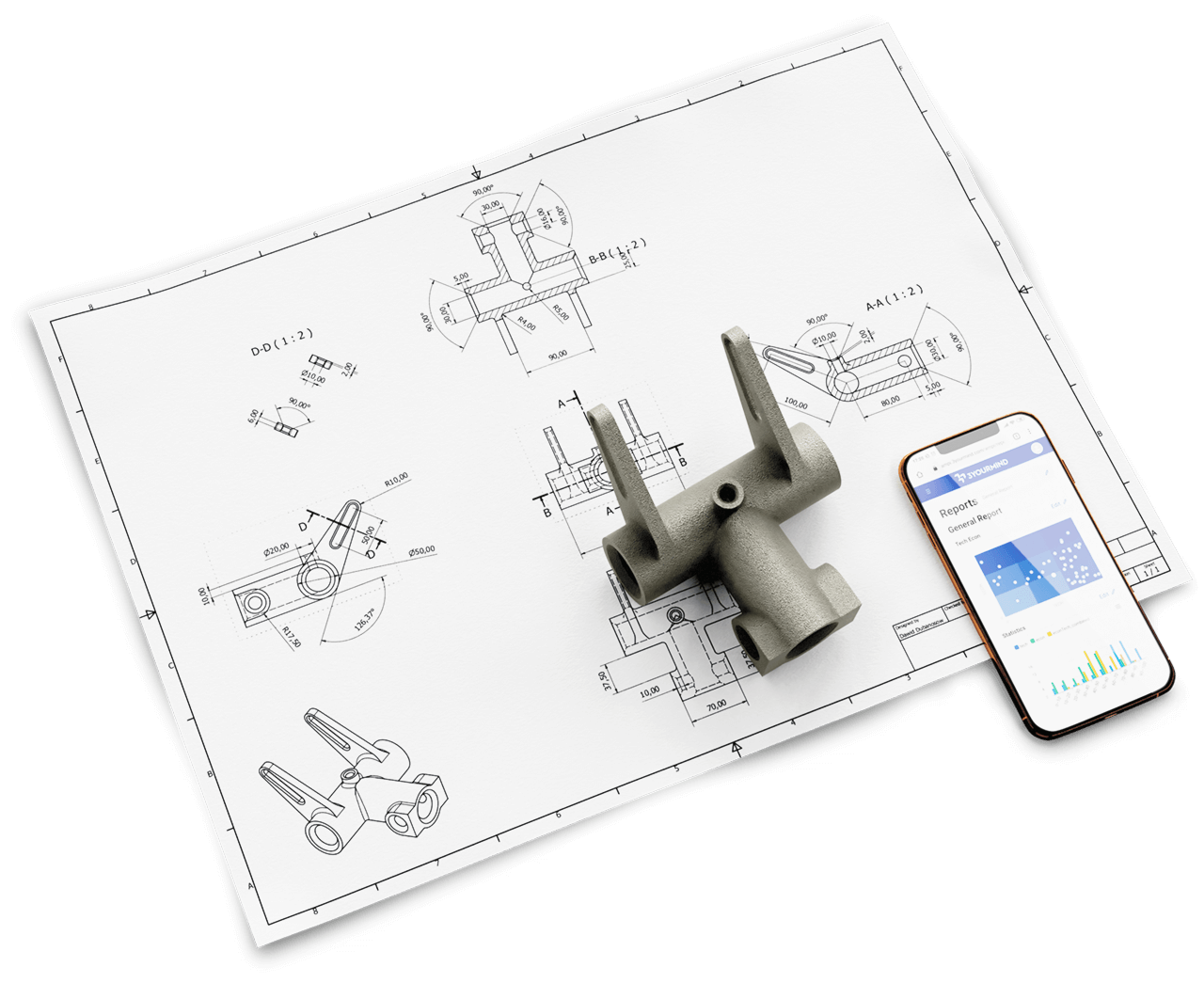

Can 3YOURMIND analyze 2D drawings?

Yes! We now offer a functionality powered by Werk24 to analyze two-dimensional technical drawings for on-demand manufacturing applications. Learn more about it here.

I don’t own the parts data. Can I still use 3YOURMIND?

That’s okay; we can work with your data (such as economic information) and connect with the parts supplier to protect intellectual property through end-to-end encryption.

How does 3YOURMIND suggest material substitutes?

3YOURMIND has the capability to suggest substitutes that can be configured within the software system. Currently, we use a market-standard material database to suggest the best material substitutes for your part.

We've also recently launched our 'Easy 3D' material ecosystem collaboration with Arkema to help customers gain more access to material recommendations.

How do I demonstrate the value of 3YOURMIND to management?

3YOURMIND's part screening and business case functionality identify cost and time savings for companies eager to identify on-demand use cases for spare parts. If you have too much inventory data or insufficient resources to analyze parts manually, 3YOURMIND can empower your organization to find suitable on-demand business cases faster.

Ask us about our pilot program to discover what value 3YOURMIND can unlock in your on-demand operations.

How much can I save using 3YOURMIND?

Depending on the size and scope of your organization, 3YOURMIND's part screening and business case solution can result in $5-9 million in savings in annual production costs, warehouse operations, and production downtime through the use of qualified on-demand parts.

In addition, firms can save upward of $60,000 in labor costs by reducing time spent identifying on-demand parts.

3YOURMIND is helping to make on-demand manufacturing accessible to more industries. Chat with a team member to see if our part screening and business case solution is right for your organization.