Is Low-Volume Production Cost-Effective?

Is there a good business case for low-volume production? In this article, learn when low-volume production is (and isn't) cost-effective.

In the dynamic landscape of modern manufacturing, companies often face the challenge of deciding whether to pursue high-volume production or opt for low-volume production. Low-volume production refers to the manufacturing of smaller quantities of parts or products. While high-volume production can offer economies of scale, low-volume production has its own merits, especially regarding cost-effectiveness. This essay explores the factors contributing to the cost-effectiveness of low-volume production in manufacturing.

What Factors Make Low Volume Production Cost Effective?

Flexibility and Customization:

One of the key advantages of low-volume production is the inherent flexibility it offers. Unlike high-volume production, where products are typically standardized and produced in large quantities, low-volume production allows for greater customization. By catering to niche markets or specific customer requirements, manufacturers can charge premium prices for their specialized products, compensating for the potentially higher per-unit costs. This flexibility also enables manufacturers to quickly adapt to changes in demand, reducing the risk of excess inventory and associated holding costs.

Reduced Inventory Costs:

Low-volume production minimizes the need for large inventories, resulting in significant cost savings. Maintaining high inventory levels in high-volume production can be expensive due to storage requirements, handling costs, and the risk of obsolescence. By producing smaller batches, manufacturers can lower their inventory carrying costs and optimize their working capital. This lean approach allows companies to focus on quality control, reduce waste, and efficiently manage their production resources, ultimately resulting in cost savings.

Lower Setup and Tooling Costs:

In high-volume production, significant investments are required for specialized tooling and setup costs, as they must be amortized over many units. Conversely, low-volume production reduces the need for extensive tooling and setup, as manufacturers can leverage existing equipment and processes. This eliminates the need for costly tooling changeovers and reduces the initial capital investment. The reduced setup costs associated with low-volume production contribute to its cost-effectiveness, making it an attractive option for manufacturing companies.

R&D and Innovation:

Low-volume production can also be a strategic avenue for research and development (R&D) and innovation. By producing parts or products in smaller quantities, manufacturers can experiment with new designs, materials, or manufacturing processes without committing to large-scale production. This enables companies to test the viability of new concepts and make necessary refinements based on feedback and demand.

Reduced Risk:

High-volume production carries inherent risks, particularly regarding market demand fluctuations and changing customer preferences. Overproduction can lead to excess inventory, resulting in significant financial losses. In contrast, low-volume production mitigates these risks by producing smaller quantities that align closely with market demand. Manufacturers can better gauge customer response and adjust production accordingly, minimizing the financial impact of sudden shifts in demand. This risk reduction can lead to improved cost-effectiveness and overall business stability.

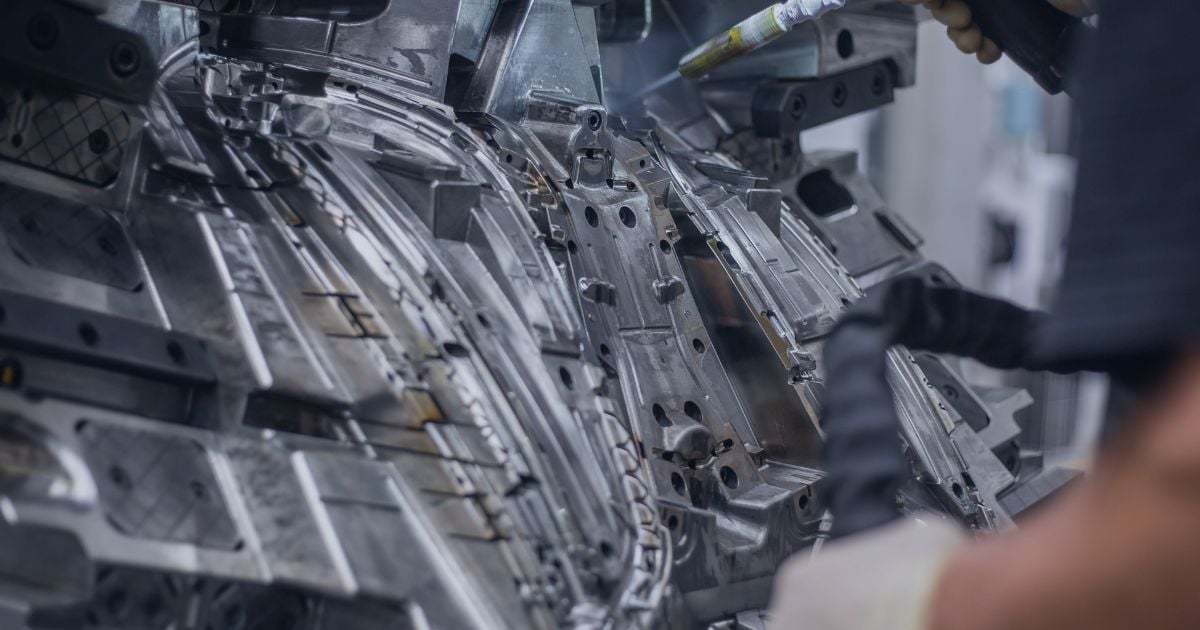

Pictured: Engineer freezing injection mold after production with dry nitrogen.

Pictured: Engineer freezing injection mold after production with dry nitrogen.

When is Low Volume Production Not Cost-Effective?

While low-volume production offers various benefits, there are situations where it may not be the most cost-effective option for manufacturing companies. One such scenario is when economies of scale are critical in reducing per-unit costs. High-volume production often allows for optimizing processes, material procurement, and labor efficiency, resulting in lower production costs. If the market demand is consistently high, producing parts in large quantities can help achieve economies of scale and drive down the overall cost per unit.

Additionally, when the cost of setup and tooling dominates the production expenses, low-volume production may not be cost-effective. In industries where specialized equipment or tooling is required, and the setup costs are significant, producing smaller quantities may not provide adequate returns on investment. The setup costs need to be spread over a sufficient number of units to make them economically viable, which is not feasible in low-volume production.

Moreover, low-volume production may not be cost-effective if the pricing dynamics in the market are highly competitive. In industries where customers prioritize price over customization or uniqueness, high-volume production allows for lower per-unit costs, enabling manufacturers to offer competitive prices and gain market share. In such cases, producing parts in low volumes might result in higher costs, making it challenging to compete effectively in the market.

3D printed parts demonstrating complex geometry and freedom of design

3D printed parts demonstrating complex geometry and freedom of design

Additive Manufacturing and Low Volume Production

Additive manufacturing, also known as 3D printing or on-demand manufacturing, is often utilized for low-volume production due to several compelling reasons. Firstly, additive manufacturing offers unparalleled design flexibility. Traditional manufacturing methods often have limitations in terms of complex geometries and intricate designs. However, with additive manufacturing, parts can be produced layer by layer, allowing for the creation of highly customized and intricate components that would be challenging or even impossible to manufacture using conventional techniques. This design freedom is particularly advantageous in low-volume production, where customers often value customization and uniqueness.

Secondly, additive manufacturing eliminates the need for expensive tooling and setup costs associated with traditional manufacturing processes. In high-volume production, the cost of creating molds, dyes, or other specialized tooling can be significant and must be amortized over many units. In contrast, additive manufacturing eliminates the need for tooling altogether, as parts are built directly from a digital model, which can be accessed via a digital inventory. This significantly reduces upfront costs, making it an attractive option for low-volume production where economies of scale may not be achieved.

Furthermore, additive manufacturing allows for on-demand production, which is highly advantageous in low-volume scenarios. Traditional manufacturing often requires forecasting and planning to meet production quantities and lead times. However, with additive manufacturing, parts can be produced as needed, reducing the risks associated with inventory management (such as implementing digital warehousing to reduce inventory costs). This is also particularly advantageous when discussing spare part management for maintenance and part obsolescence because it can mitigate operational downtime by reducing lengthy production lead times that are often necessary to replace legacy parts.

Additive Manufacturing to Justify Low-Volume Production

Want to learn more about how additive manufacturing can make low-volume production more cost-effective?

Tune into this episode of 3D Talk Show to learn from experts across the additive manufacturing industry as they discuss tactics for identifying the best use cases for additive manufacturing and when to justify the cost.