On Demand Manufacturing: What It Is and How To Use It

Discover why on-demand manufacturing is gaining momentum as an alternative manufacturing model.

In recent years, on-demand manufacturing has gained significant attention in enterprise businesses as an alternative to traditional manufacturing methods. Whereas conventional methods require high-volume production to be cost-effective, on-demand manufacturing produces low- to mid-volume goods when and where needed using 3D printing, CNC machining, and water jet technologies.

Disrupted supply chains, off-shore manufacturing, and skilled labor shortages have all contributed to the conversation regarding current manufacturing methods. However, enabling the widespread adoption of next-generation manufacturing methods requires changing the current manufacturing paradigm to evolve harmoniously with all Industry 4.0 elements, including decentralization, interoperability, big data, and the Industrial Internet of Things (IIoT).

In this article, we'll explore the importance of on-demand manufacturing and a few of its benefits.

Why is On-Demand Manufacturing Important?

On-demand manufacturing refers to creating products only when there is a demand instead of creating them in bulk quantities and storing them in a warehouse. Although globalization enabled a manufacturing culture of cheap, ‘just-in-time’ goods, the events of the last few years, including global supply chain constraints due to the COVID-19 pandemic and geopolitical conflicts, have underlined the importance of economic self-reliance and decentralized manufacturing.

3YOURMIND enables on-demand manufacturing across distributed production facilities.

The allure of on-demand manufacturing is its ability to make organizations more reactive to changing circumstances. For example, suppose a critical spare part breaks, and replacement parts are located at an off-site warehouse.

In that case, on-demand manufacturing methods can produce the part with shorter production lead time and less operational downtime. Additive manufacturing (AM) is a central player in transitioning away from rigid manufacturing mechanisms and precarious supply chains.

ASTM International defines AM as “a process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies.” Additive manufacturing offers benefits such as design flexibility to create parts conventionally made from multiple components into a singular printed piece. In addition, its ‘freeform’ layer-by-layer printing capabilities empower lightweight designs, critical for industries like aerospace and defense.

The potential of additive technology to support on-demand initiatives is also gaining high-level support in government. For example, in May of 2022, U.S. President Joe Biden announced the Additive Manufacturing Forward program to accelerate the adoption of additive manufacturing technology between major U.S. original equipment manufacturers (OEM) and their small and medium enterprise (SME) suppliers.

The partnership program is designed for OEMs to send ‘demand signals’ to SME suppliers to encourage suppliers to invest more in AM technology with less perceived financial risk. As a result, SME suppliers can utilize OEM expertise to invest in new machines, gain access to technical assistance, train workers, and work together to develop AM standards.2

The AM Forward program is a significant indicator that on-demand production is piercing traditional manufacturing barriers, demonstrating that the global manufacturing industry is more receptive to on-demand manufacturing opportunities.

Why Use On-Demand Manufacturing?

Reduces Sunk Warehousing Costs

Enterprise businesses can leverage on-demand manufacturing in a variety of ways. Firstly, it reduces inventory costs by eliminating the need to store large quantities of products in a warehouse. Instead, they can produce products only when there is a demand for them, which results in a leaner, more efficient supply chain.

Enables More Agile Production Decisions

Secondly, on-demand manufacturing allows companies to respond quickly to changes in demand. This capability is particularly important in defense and humanitarian deployment because it enables response organizations to react to changing needs.

To illustrate this, since the spring of 2022, 3YOURMIND and Sygnis have successfully enabled on-demand manufacturing to support defense efforts in Ukraine. By listening to the needs of defense forces on the front, production facilities can produce defense and medical aid equipment based on changing circumstances. Whether it's applications like drone equipment, tourniquets, or periscopes, on-demand manufacturing can ramp up or scale down production with less disruption.

Get Spare Parts Faster From Trusted Suppliers

Traditional manufacturing methods can take weeks or even months to produce a spare part. With on-demand manufacturing, parts can be produced in a matter of hours or days, depending on the complexity and size of the part. Because on-demand manufacturing eliminates the need for expensive tooling or molds typically required for traditional manufacturing methods, businesses can produce spare parts at low volumes to improve cost-effectiveness.

In addition, on-demand manufacturing can be performed locally, meaning businesses can get the parts they need quickly and easily without waiting for them shipped from overseas. This is particularly critical for industries operating offshore, like oil and gas. By producing a part closer to its end-use, industries can mitigate operational downtime, resulting in significant revenue savings.

More Sustainable Manufacturing Practices

On-demand manufacturing can help companies to reduce their environmental impact by minimizing waste and reducing the need for transportation. Traditional manufacturing methods often involve the production of large quantities of products that may not be sold, resulting in excess inventory and waste. On-demand manufacturing reduces this waste by producing only what is required, which helps to reduce the environmental impact of the manufacturing process.

3YOURMIND: The Leading On-Demand Manufacturing Software

On-demand manufacturing is revolutionizing the manufacturing industry through technological innovation and the democratization of manufacturing processes. 3YOURMIND is at the forefront by offering a comprehensive software solution to help businesses navigate on-demand manufacturing for their unique workflows.

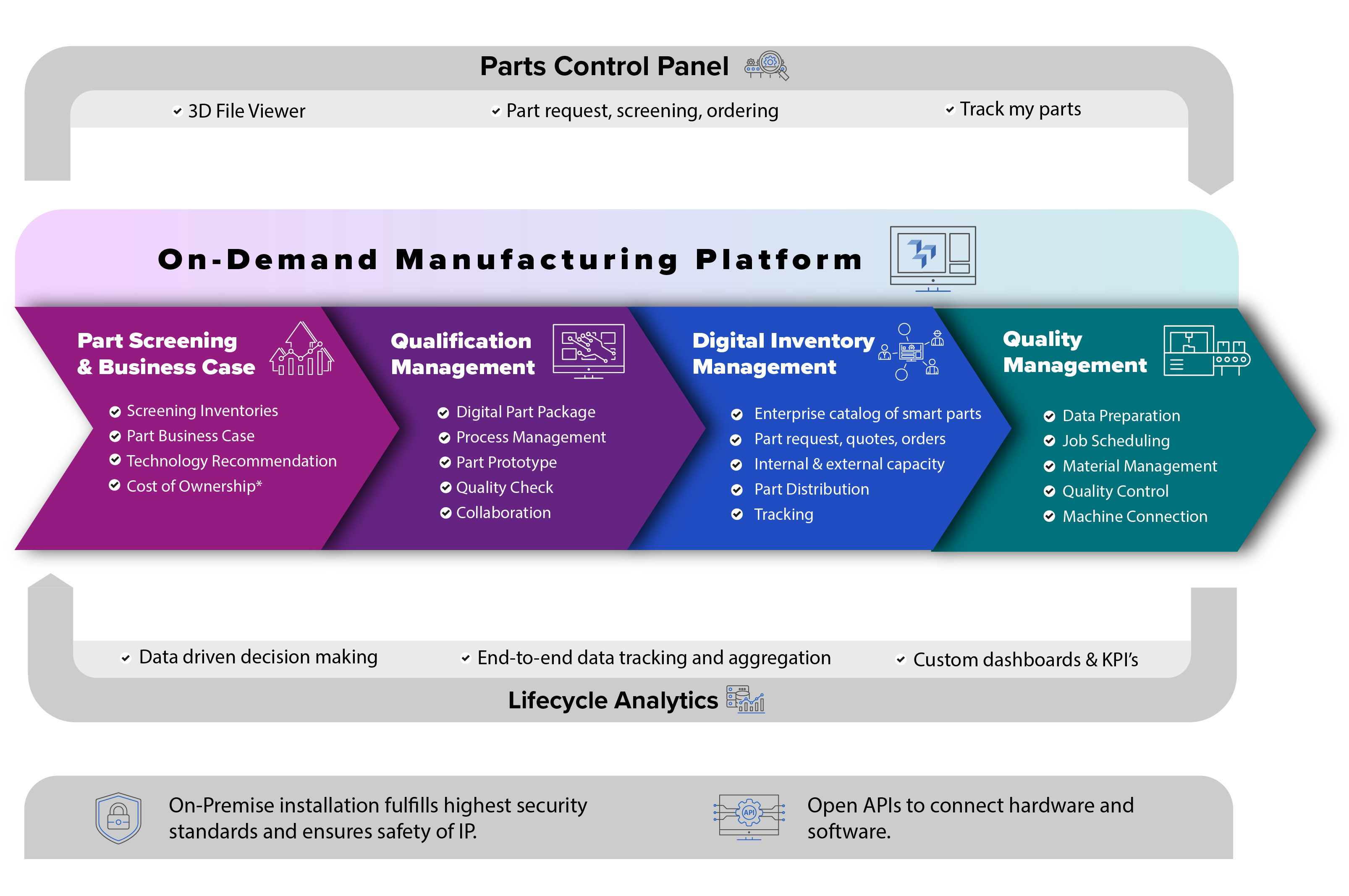

The process starts with part screening, where 3YOURMIND software scans part files for numeric data, 2D, and 3D files to identify priority parts for 3D printing that demonstrate strong business cases. This automated process generates significant time savings, enabling additive manufacturing experts to focus their efforts on qualifying the most suitable parts.

Once parts are identified, the software assists engineers with tools to streamline part qualification to ensure that parts meet quality standards and can be easily replicated.

After a part has been cleared for on-demand production, it can be added to the digital inventory, which functions as a part catalog, enabling organizations like OEMs to securely share IP with approved suppliers. From there, OEMs can view price quotes from different suppliers, submit orders, and make custom requests within a single platform.

For parts produced in-house, production quality management ensures that OEMs have the tools to oversee their own on-demand production. 3YOURMIND software connects to multiple machine types, giving OEMs the tools to schedule and prepare job builds across different machines, materials, and additive technologies.

As a result of using 3YOURMIND, companies get access to the entire data thread, from part identification to production. This data is critical to performance because it enables part traceability, dials-in quality assurance, and populates dashboard analytics to help organizations make informed decision-making.

Download Your Free On-Demand Manufacturing Guide

On-demand is an innovative model that addresses many of the current pain points experienced with conventional manufacturing.

Check out our free eBook to learn methods for enabling on-demand manufacturing, explore customer use cases, and find what questions you should be asking your manufacturing software vendor.