5 Technology Trends that Will Shape Industry 4.0

Explore five technology trends that will drive the next wave of industry.

Industry 4.0, also known as the fourth industrial revolution, is gradually occuring worldwide. It features integrating digital technologies with traditional manufacturing processes to enhance efficiency, productivity, and profitability. Industry 4.0 is expected to revolutionize various industries, and several incoming trends are set to change how we work and live.

In this article, we will discuss several incoming Industry 4.0 trends and why they are important.

5 Trends We Expect to See With Industry 4.0

Additive Manufacturing

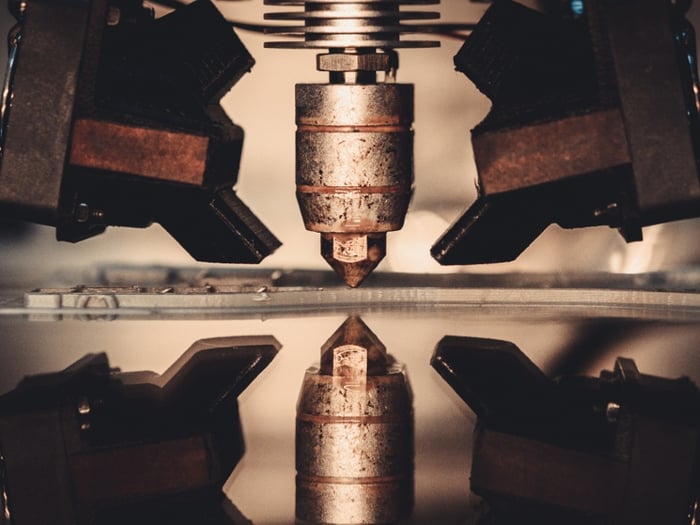

Additive manufacturing, also known as 3D printing, is a process that builds a three-dimensional object by adding layer upon layer of material. This technology has been around since the 1980s but has recently gained popularity due to the decreased cost of 3D printers. The process involves the creation of a digital model of the object to be printed, which is then sent to the printer. The printer then builds the object by adding layer upon layer of material until the final product is complete.

Additive manufacturing is a key trend in Industry 4.0 by enabling advanced manufacturers to produce complex parts and products more efficiently and cost-effectively. Additive manufacturing can also reduce waste, using only the materials required to produce a part.

Additive manufacturing can also be deployed quickly, which makes a compelling use case for crisis response. Learn how the additive manufacturing industry jumped into action in the initial weeks of the war in Ukraine.

Internet of Things (IoT)

The Internet of Things (IoT) is a network of interconnected devices that communicate with each other and humans. It is a key trend in Industry 4.0 and is set to transform the manufacturing industry. IoT technology enables machines and devices to communicate, providing real-time data on production processes, equipment performance, and inventory levels.

IoT can also be thought of as machine connectivity, which is a keystone in other Industry 4.0 trends like additive manufacturing. By connecting hardware machines like 3D printers to computer software, manufacturers can gain access to data critical to the product's lifecycle. This data can be used to certify parts, optimize production processes, reduce waste, and improve efficiency. IoT can also enable predictive maintenance, reducing dewntime and maintenance costs.

Learn more about 3YOURMIND's machine connectivity capabilities on our API Integrations page.

Big Data Analytics

Big Data Analytics analyzes large datasets to identify patterns and trends. In Industry 4.0, big data analytics can analyze production processes, equipment performance, and inventory levels to optimize production, reduce waste, and improve efficiency. Big data can bring awareness potential quality issues, enabling manufacturers to address them before they become problematic.

Artificial Intelligence (AI)

Artificial Intelligence (AI) is another key trend in Industry 4.0. AI technology can analyze vast amounts of data and identify patterns, enabling manufacturers to make informed decisions. AI can optimize production processes, reducing waste and improving efficiency.

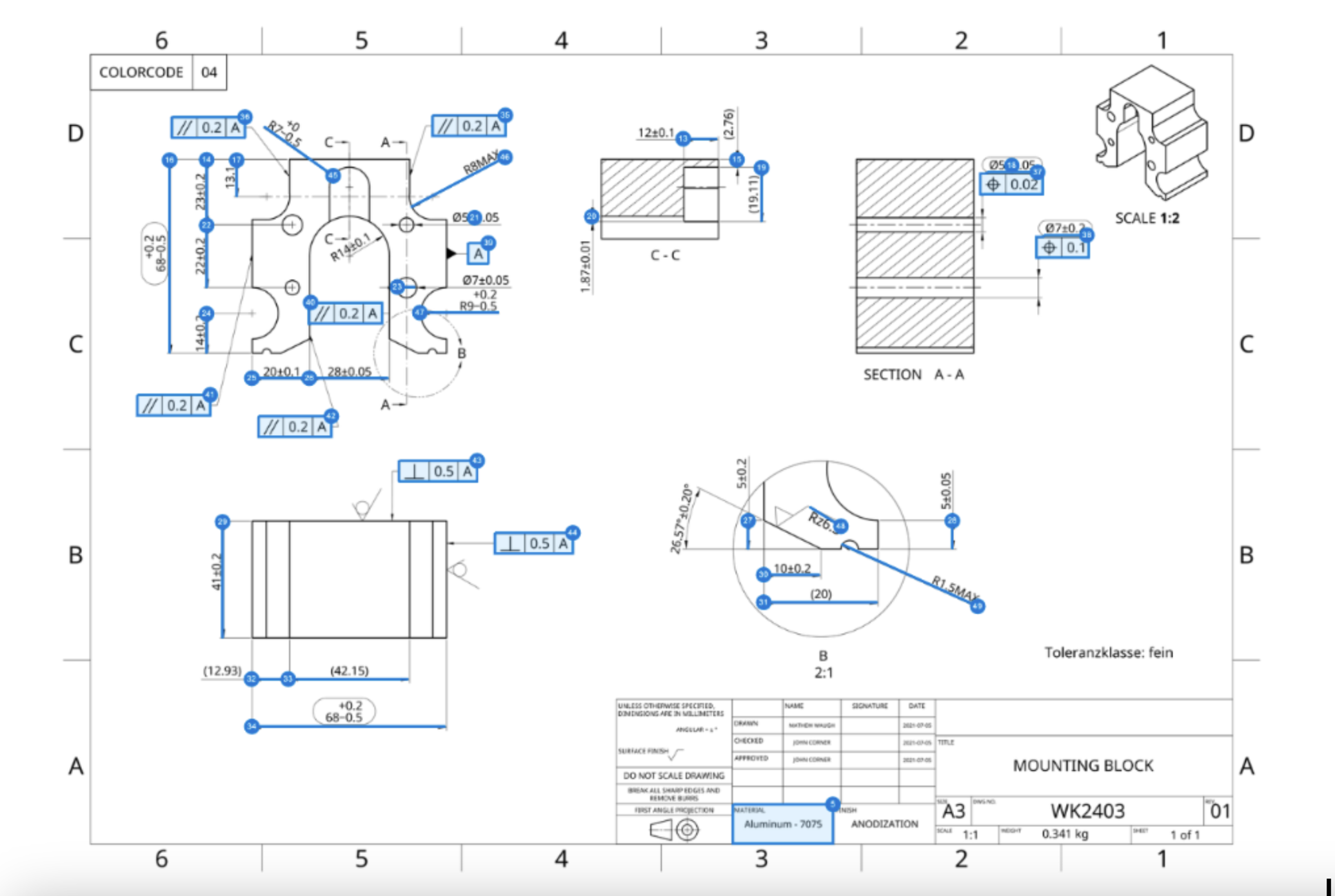

At 3YOURMIND, we leverage AI technology powered by Werk24 to evaluate two-dimensional technical drawings for 3D printability. For customers, this means spending significantly less time identifying parts for 3D printing.

AI analyzes 2D drawings for production cost savings using additive manufacturing.

AI analyzes 2D drawings for production cost savings using additive manufacturing.

Instead of evaluating thousands or tens of thousands of parts individually, users can upload 2D part drawings. AI then analyzes data points from the technical drawings to determine whether cost savings can be achieved using 3D printing. As a result, organizations can focus their efforts on qualifying parts with the best business use cases for Industry 4.0.

Digital Twins

Digital Twins are virtual replicas of physical assets, products, or processes. In Industry 4.0, digital twins can be used to simulate production processes, enabling manufacturers to identify potential issues before they occur.

3YOURMIND's digital inventory functions as a digital twin of physical parts.

For example, 3YOURMIND's digital inventory creates digital replicas of 3D-printable parts, enabling experts to view part specifications, order parts, and manage inventories via an online platform. Because parts can be printed on-demand, organizations can reduce the number of stored parts. As a result, companies begin to print parts as needed from the 'digital twins,' rather than producing parts using conventional manufacturing methods like CNC machining and injection molding.

Get a Jump on Industry 4.0 With Your Free On-Demand Guide

Industry 4.0 is set to revolutionize how we work and live, and these trends are just the beginning. It is important for manufacturers to embrace these trends and invest in the technologies that will enable them to stay ahead of the competition.

In this free step-by-step guide to on-demand additive manufacturing, you'll explore:

- Reasons why your business should pursue on-demand manufacturing

- Five keys to successfully implement on-demand manufacturing and built more robust supply chains.

- Two validated use cases from the railway and automotive industries

- Learn how to assess and select the right software partner for on-demand manufacturing.