What are the Different Types of Advanced Manufacturing?

What is advanced manufacturing, and why is it important?

In this article, we'll discuss the different types of advanced manufacturing and how they are transforming the manufacturing industry.

Advanced manufacturing is a broad term that refers to the use of innovative technologies and processes to improve the efficiency and productivity of manufacturing. Advanced manufacturing encompasses various techniques, including automation, additive manufacturing, and robotics. In recent years, advanced manufacturing has become increasingly important as businesses seek to improve efficiency, reduce costs, and produce higher-quality products.

5 Prominent Technologies in Advanced Manufacturing

Additive Manufacturing

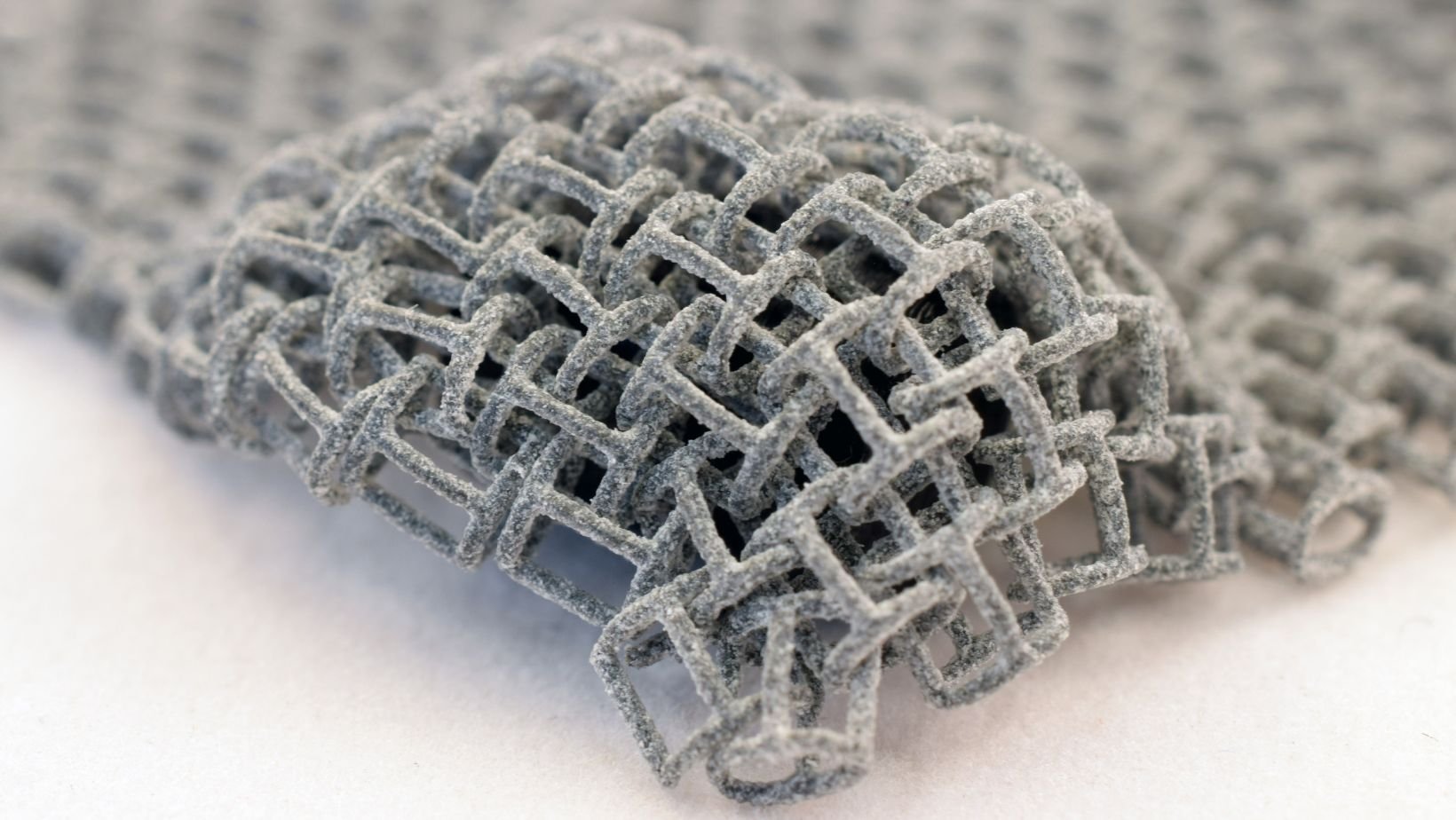

Additive manufacturing, also known as 3D printing, is a process that builds a three-dimensional object by adding layer upon layer of material. This technology has been around since the 1980s but has recently gained popularity due to the decreased cost of 3D printers. The process involves the creation of a digital model of the object to be printed, which is then sent to the printer. The printer then builds the object by adding layer upon layer of material until the final product is complete.

The advantages of additive manufacturing are numerous. It allows for the creation of complex shapes and designs that would be difficult or impossible to create with traditional manufacturing methods. It also reduces material waste and can produce parts with greater accuracy and consistency. Additive manufacturing is particularly useful in the medical industry, where it is used to produce custom implants and prosthetics.

Digital Manufacturing

Digital manufacturing involves using digital technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to automate manufacturing processes. CAD software is used to create a digital model of the product to be manufactured, which is then used by CAM software to control the manufacturing process. This technology allows for the creation of complex designs and enables manufacturers to produce products with greater precision and accuracy.

One of the key advantages of digital manufacturing is the ability to simulate the manufacturing process before it takes place. This allows manufacturers to identify potential issues and make changes before any materials are wasted. Digital manufacturing also enables greater customization of products, as digital models can be easily modified to meet specific requirements.

Robotics

Robotics involves using robots to perform manufacturing tasks traditionally carried out by humans. This technology has been around for many years, but recent advances in robotics have led to significant improvements in efficiency and productivity. Robots can be programmed to perform various tasks, including assembly, welding, and material handling.

The advantages of robotics in manufacturing are numerous. Robots can work 24/7 without breaks or the need for rest, which improves efficiency and reduces costs. They are also able to perform tasks that are dangerous or unpleasant for humans, such as working in hazardous environments or handling toxic materials. Robotics also allows for greater manufacturing precision and accuracy, improving product quality.

Smart Manufacturing

Smart manufacturing involves using interconnected systems and devices to optimize the manufacturing process. This technology, also known as the Industrial Internet of Things (IIoT), involves using sensors, data analytics, and machine learning to improve efficiency and productivity. Smart manufacturing enables manufacturers to collect and analyze data from various stages of manufacturing, making more informed decisions and optimizing their operations.

The advantages of smart manufacturing are significant. It allows manufacturers to identify and address real-time issues, reducing downtime and improving efficiency. It also enables greater customization of products and can improve product quality by identifying and addressing issues before they become major problems.

Advanced Materials

Advanced materials refer to materials that have been specifically engineered to have specific properties or characteristics. Advanced manufacturing often uses these materials to improve product performance and durability. Examples of advanced materials include carbon fiber composites, ceramics, and nanomaterials. The advantages of advanced materials in manufacturing are numerous. They can improve product performance by making products stronger, lighter, or more durable. They can also reduce costs by reducing the need for maintenance or replacement. Advanced materials are particularly useful in industries such as aerospace.

What are the Benefits of Advanced Manufacturing?

Increased Efficiency

One of the primary benefits of advanced manufacturing is increased efficiency. Technologies such as robotics and smart manufacturing enable manufacturers to automate manufacturing processes and improve productivity. Robots can work 24/7 without breaks or the need for rest, which improves efficiency and reduces costs. Smart manufacturing allows manufacturers to collect and analyze data from various stages of manufacturing, identifying and addressing issues in real-time. This reduces downtime and improves efficiency.

Reduced Costs

Advanced manufacturing can also lead to reduced costs. Technologies such as additive manufacturing can reduce material waste and improve the efficiency of the manufacturing process. This can lead to significant cost savings over traditional manufacturing methods. Digital manufacturing enables manufacturers to simulate the process before it takes place, allowing them to identify potential issues and make changes before materials are wasted. This reduces costs and improves efficiency.

Improved Product Quality

Advanced manufacturing can also improve product quality. Technologies such as additive manufacturing and robotics enable greater manufacturing precision and accuracy, improving product quality. Advanced materials can also improve product performance by making products stronger, lighter, or more durable. Smart manufacturing allows manufacturers to identify and address issues before they become major problems, improving product quality and reducing the need for costly recalls.

Greater Customization

Another benefit of advanced manufacturing is greater customization. Digital manufacturing enables manufacturers to create custom products quickly and easily by modifying digital models. Additive manufacturing allows for the creation of complex shapes and designs that would be difficult or impossible to create with traditional manufacturing methods. This enables manufacturers to meet specific customer requirements and differentiate themselves from competitors.

Environmental Benefits

Advanced manufacturing can also have environmental benefits. Technologies such as additive manufacturing and digital manufacturing can reduce material waste and energy consumption, reducing the environmental impact of manufacturing. Advanced materials can also reduce the need for maintenance or replacement, reducing the amount of waste produced. Smart manufacturing can also reduce the environmental impact of manufacturing by identifying and addressing issues before they become major problems.

How 3YOURMIND Supports Advanced Manufacturing Initiatives

3YOURMIND helps companies realize advanced manufacturing practices.

Advanced manufacturing is a broad field. 3YOURMIND marries elements from advanced martierials, additive, digital, and smart manufacturing to enable what is known as on-demand manufacturing. On-demand manufacturing refers to the process of producing low- to mid-volume goods where and where they're needed using technologies like 3D printing, CNC machining, and water jetting technologies.

3YOURMIND's on-demand manufacturing platform acts as a digital thread, connecting processes like 3D part screening and qualification to digital inventory and production management. For original equipment manufacturers and suppliers sourcing spare parts or obsolete equipment, on-demand manufacturing offers a solutions to produce parts closer to their end-use and in less time than conventional manufacturing methods.

At its core, 3YOURMIND enables businesses to develop digital inventories of 3D-printable parts and connects them with a simple workflow to order parts from internal and external suppliers to realize on-demand and distributed manufacturing models.

Get Your Free Step-by-Step Guide to On-Demand Manufacturing

Interested in on-demand manufacturing but don't know where to start?

By using this guide, CIOs, service operation managers, supply chain managers, AM experts, and engineers create a strategic roadmap for on-demand manufacturing.